Custom Search

|

|

|

||

Expansion Tanks

Expansion tanks are normally used in the collector loop of closed-loop systems.

Occasionally they are found in the cold water supply to storage tanks, but only if a

backflow preventer or check valve is also in that line.

CAUTION

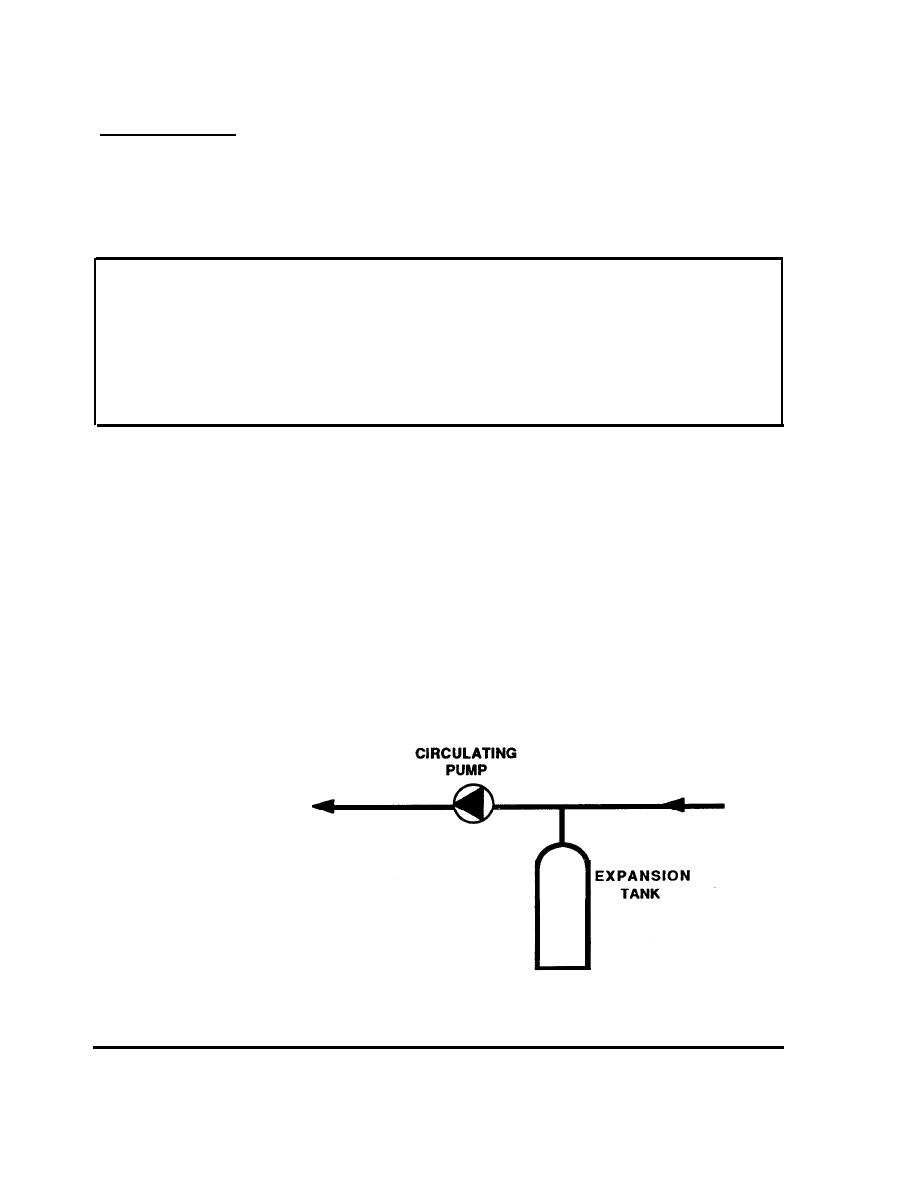

Whenever an expansion tank is installed in a loop with

a pump, it must be on the suction side of the

pump. (Figure 2-33) Installation of an expansion tank

on the discharge side of the pump can result in pump

cavitation and damage.

Because fluids are not compressible, expansion tanks are needed to maintain a

fairly stable system pressure. Without one, a closed piping system undergoing

temperature changes would fluctuate from zero pounds to many hundreds of

pounds of pressure.

Expansion tanks for solar fluids are normally constructed of raw. or galvanized

steel. (Figure 2-34) Some have a flexible internal diaphragm maintaining a separate

air cushion. (Figure 2-35) Diaphragm-type tanks are preferred for solar applications.

The air side of the tank usually has a Schrader valve (similar to the ones used on

automobile tires) to allow checking and changing the air pressure. The air cushion

normally comes pre-charged from the factory at 12 PSI.

FIGURE 2-33

Proper Expansion

Tank Placement

OPERATION

38

2.7 COMPONENT OPERATION

|

|

|

|

||