Custom Search

|

|

|

||

Before replacing the absorber in the collector, spray black high-temperature

(barbecue or stove) paint on the insulation where the hole in the fin will be. Use the

same paint on the repaired section of the tube.

Before installing a repaired absorber into the collector, it may be worthwhile to

pressure test it. Use compressed air, and keep the absorber out of the sun. One

hour is an adequate time period. The test pressure should be at approximately the

same pressure as the collector loop pressure relief valve release pressure.

Frame Ground

Every collector with a sensor must have its frame grounded. This ground helps

prevent damage to the system control.

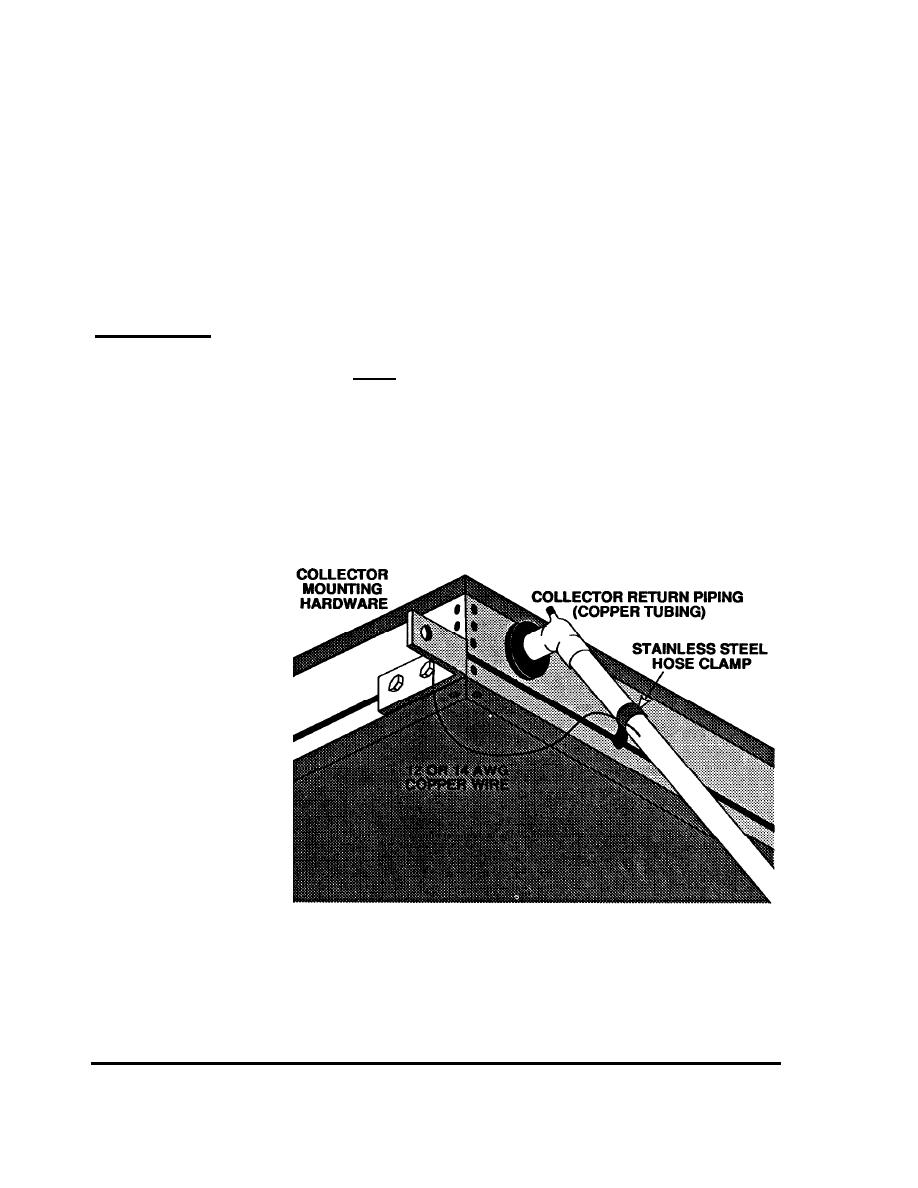

The typical grounding method is simple. A short piece of 12 or 14 gauge copper

wire is stripped at each end about two inches. One end is hose clamped to an

absorber plate header. The other end is connected to the collector frame. The

frame connection usually involves the collector mounting hardware (Figure 5-9).

FIGURE 5-9

A Properly Grounded

Collector

After installing or reconnecting this ground, use an ohmmeter to make sure there is

a solid electrical connection between the absorber piping and the frame. Cover the

junction between the aluminum frame and the copper wire with silicone sealant to

reduce galvanic corrosion.

REPAIR

152

5.2 REPAIR PROCEDURES

|

|

|

|

||