Custom Search

|

|

|

||

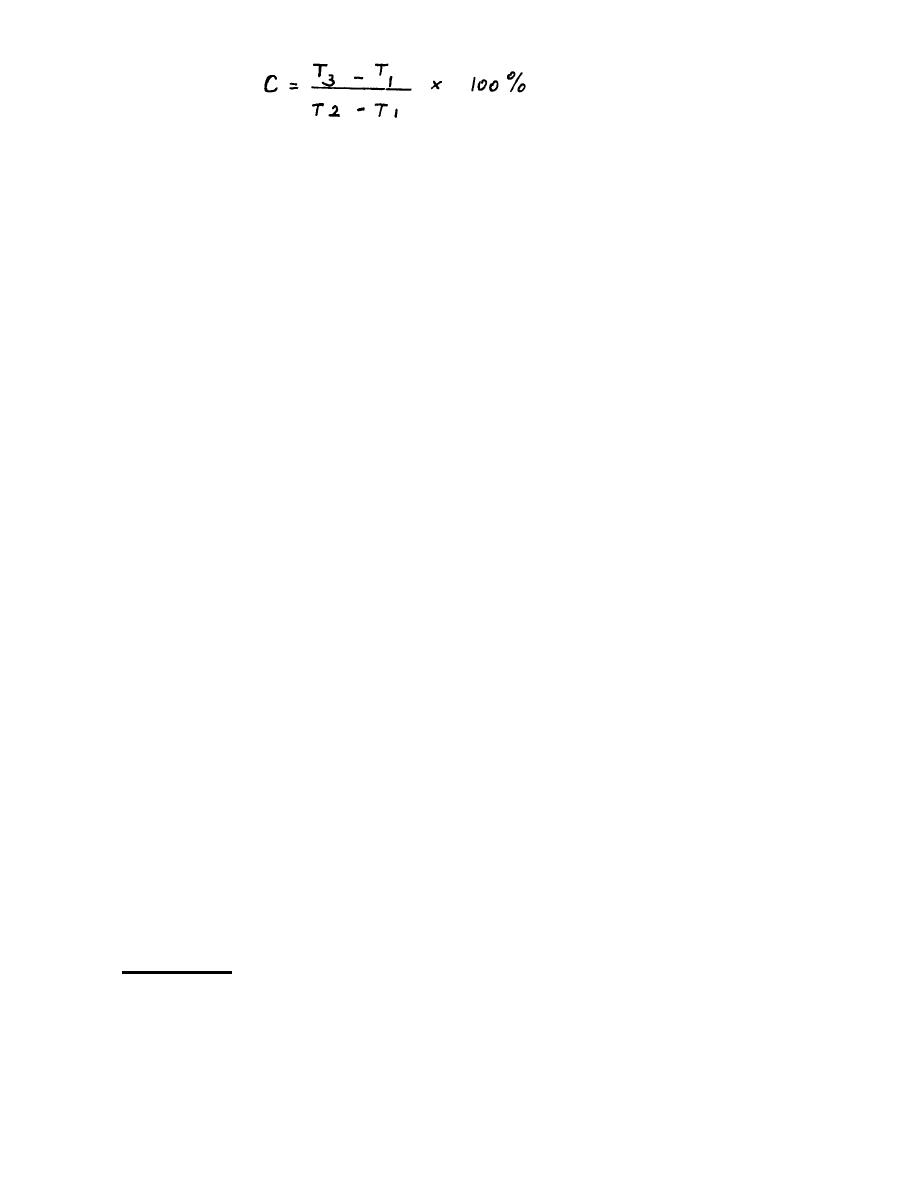

Some inherent errors exist due to the assumptions used. This method is

idea l for continuous monitoring if automatic recording devices a re used and

is particularly helpful when blending oils of nearly equal speci fic

gravities.

3.7 VISCOSITY CONTROL. Waste oil added to regular fuel affects the

viscosity of. the blend and,. hence, the fuel flow rate and nozzle spray

.

characteristics.

To minimize the requirements for burner adjustments the

firing temperature of a blend should be controlled so that its viscosity is

nearly the same as that of the regular fuel oil at its normal firing

temperature. The viscosity variation with the temperature of typical fuel

oils may be estimated by using the viscosity-temperature charts for liquid

petroleum products `in Schmidt's Fuel Oil Manual. A working chart for

determining the approximate operating temperature of fuel oil blends is

shown in Figure 3-4. The one on the left is used to determine the

viscosity of a blend of two oils of different viscosities (all in SUS* at

lOOoF), and the one on the right shows the temperature variation of

viscosity for oils whose viscosities at 100F are known. The use of these

graphs is illustrated in the following example:

A burner is designed for burning heavy fuel oil with a viscosity of

1,000 SUS at 100F. This oil is heated to 180F to achieve

satisfactory firing. A light waste oil with a viscosity of 50 SUS

at 100F will be blended into the heavy fuel oil to supplement the

boiler fuel. To fully utilize this light waste oil, its

concentration in the blend is determined to be 30 percent. What is

the satisfactory operating temperature of this blend?

From the right-hand graph of Figure 3-4, along the diagonal line

labeled 1,000 SUS, we find that the viscosity of this oil at 180F

is 125 SUS. This is also the viscosity of the blend needed in

order to achieve the desired performance. From the left-hand

graph, a line is drawn connecting 1,000 SUS for the high viscosity

component and 50 SUS for the low viscosity component to determine

the viscosity of a 30 percent waste oil blend which is slightly

less than 300 SUS. Again on the ri ght-hand side of the graph,

along the line labeled 300 SUS, we find that to attain 125 SUS the

oil should be heated to 140F. Th is is shown in the graphical

construction.

3.8 BURNER MODIFICATIONS. Minor adjustments are sometimes necessary to

correct unstable combustion and smoke emission similar to the routine

adjustments for firing clean fuel.

*Saybolt Universal Seconds.

29

|

|

|

|

||