Custom Search

|

|

|

||

T M 5-685/NAVFAC MO-912

system must rotate (crank) the engine at a speed

(2) Air starting. Some larger engines may use

sufficient to raise the cylinder air charge to the fuel

an air starting system. Compressed air at a pres-

igniting temperature. See figure 3-6.

sure of 250 or 300 psi is delivered to the working

a. Types. Two types of starting systems are avail-

cylinder's combustion chambers during the power

able for the required automatic start-up capability:

stroke. This action results in positive and fast rota-

electric starting and air starting.

tion (cranking). Depending on the manufacturer's

(1) Electric starting. Most small diesel engines

design, compressed air can be delivered to all or

use an electric starting system. This type of system

selected cylinders. This type of system requires an

is generally similar to a starter for an automotive

air compressor and receivers or air bottles for stor-

gasoline engine. Smaller diesel engines use a l2-

age of compressed air.

volt battery-powered system for cranking. Starter

(3) Air starter motor. Pneumatic air starter mo-

and battery systems of 24, 32, and 48 volts are often

tors are highly reliable. Air starter motors develop

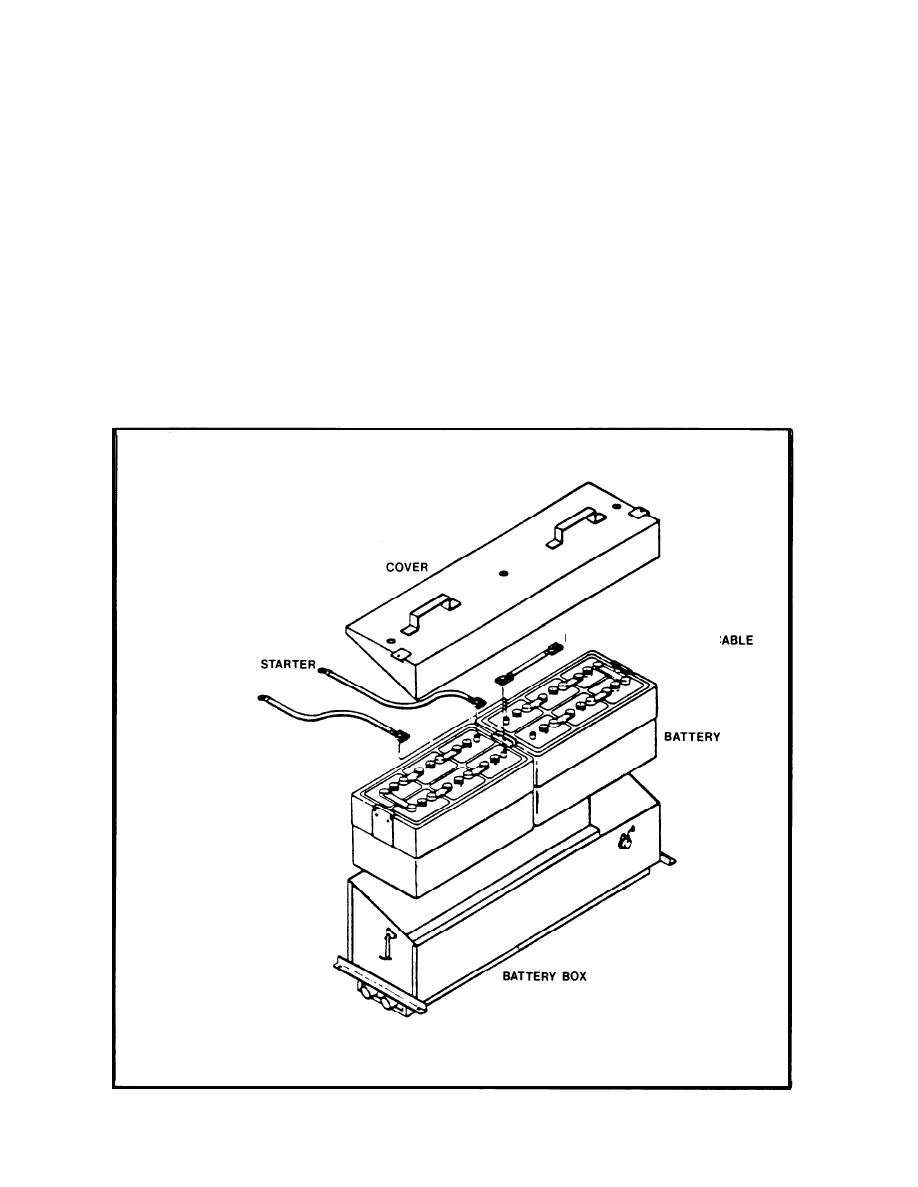

used for larger engines. A typical system consists of

enough torque to spin the engine at twice the crank-

storage batteries (as required for voltage output)

ing speed in half the time required by electric

connected in series, a battery charging system, and

starter motors. Compressed air at a pressure of 110

the necessary grounding and connecting cables. See

to 250 psi is stored in storage tanks, regulated to

figure 3-10.

110 psi and piped to the air motor. A check valve

BATTERY CONNECTING C

CABLE TO

CABLE TO GROUND

Figure 3-10. Battery for engine starting system.

3-16

|

|

|

|

||