Custom Search

|

|

|

||

TM 5-685/NAVFAC MO-912

3-15. Principles of operation.

the combustor provide a spark to ignite the fuel/air

mixture for engine start-up. The igniters are deac-

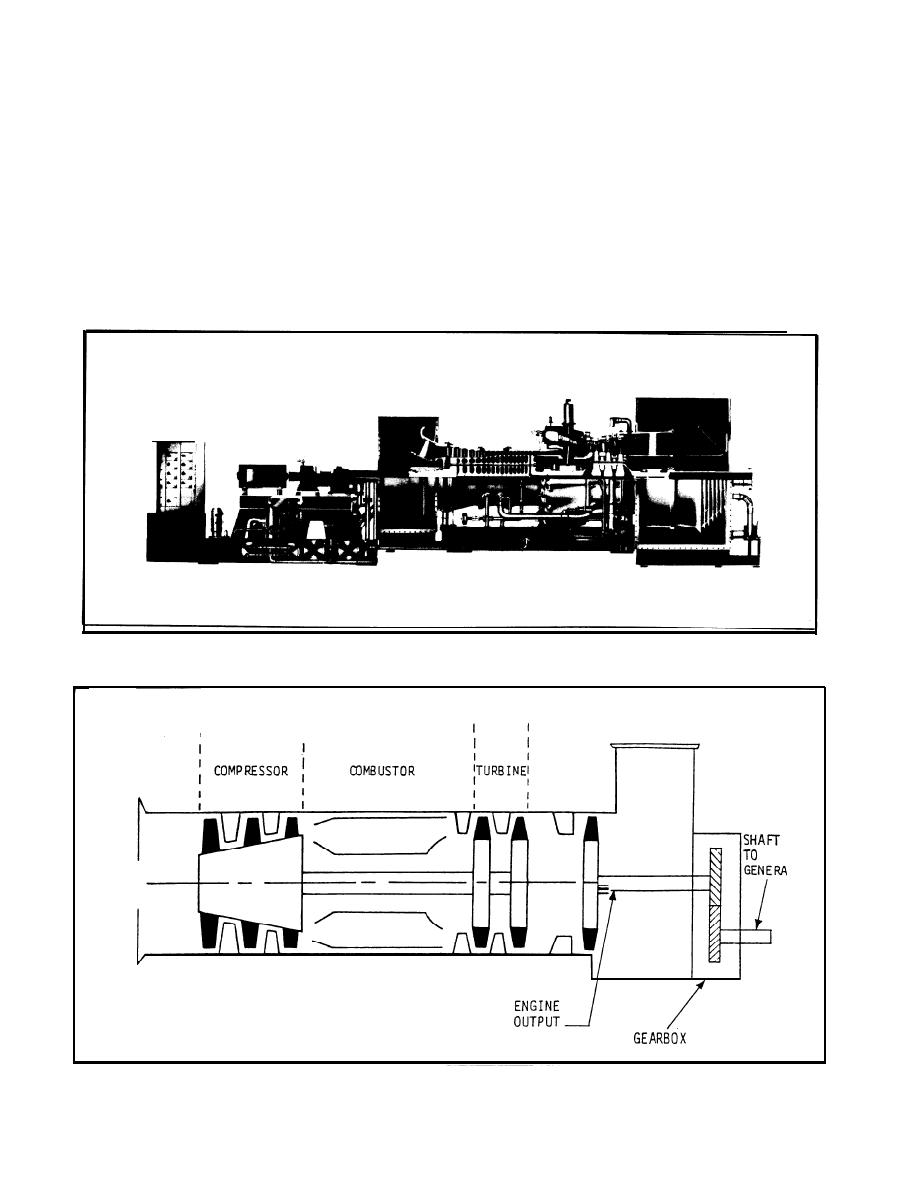

a. Components. A typical gas turbine engine con-

tivated after start-up has been accomplished. Hot

sists of a compressor, combustor and turbine (see fig

combustion gases are expelled through the turbine.

3-20).

(3) The turbine extracts energy from the hot

(1) The compressor is driven by the turbine

gases, converting it to rotary power which drives

through a common shaft. Air enters the compressor

the compressor and any load, such as a generator.

via an inlet duct. The compressor increases the air

Exhaust gases are vented via ductwork to the atmo-

pressure and reduces the air volume as it pumps air

to the combustor and through the engine.

sphere.

(2) Fuel (liquid and/or natural gas) is delivered

(4) The air intake for a gas turbine engine usu-

to the combustor by a fuel system consisting of a

ally consists of a plenum chamber with a screened

manifold, tubes, and nozzles. Electrical igniters in

inlet duct opening. The plenum chamber and duct

Figure 3-19. Typical gas turbine engine for driving electric power generator.

DUCT

I

I

TOR

INLET

DUCT

SHAFT

Figure 3-20. Gas turbine engine, turboshaft.

3-28

|

|

|

|

||