Custom Search

|

|

|

||

TM 5-685/NAVFAC MO-912

HIGH PRESSURE

TURBINE OUTER CASING

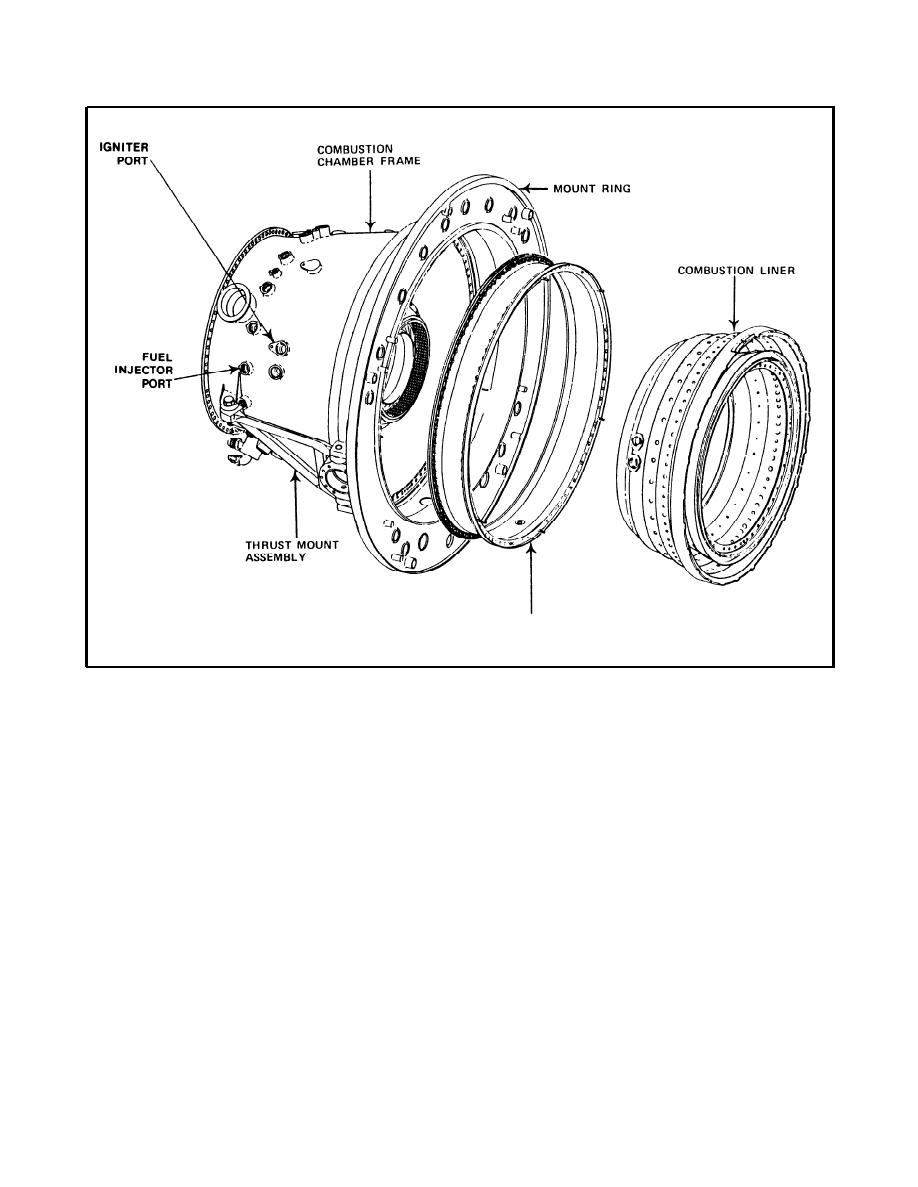

Figure 3--22. Engine combustion section.

bution to bearings. Off-engine components include

(3) Film. Film cooling is a process whereby a

flexible oil lines between on-engine and off-engine

layer of cooling air is maintained between high tem-

components, oil cooler, oil tank, lubrication supply

perature gases and the external surfaces of the tur-

differential pressure sensor, and lubrication pump.

bine blades and vanes. In general, film cooling is the

Oil is supplied by jet or spray to bearings in other

most effective type.

areas via tubes. The engine starter is usually lo-

3-18. Lubrication system.

cated in an accessory gearbox.

(1) A-Sump. Oil for A- sump components is usu-

a. The lubrication system for a gas turbine en-

ally piped from a gearbox into the sump. Internal

gine is usually self-contained with the engine and

supplies oil for lubrication and cooling during en-

passages and manifolding carry the oil to the

A-sump housing. A double-headed nozzle supplies

gine operation (see fig 3-27). Engine bearings in the

oil to the forward bearing and the undercooled car-

compressor, combustor, and turbine areas (identi-

bon seal runner for the bearing. The second bearing

fied as areas A, B, and C, respectively) are supplied

is lubricated through oil nozzles mounted on a

by the system. System pressure is approximately 75

power take-off housing. Oil is supplied to the rear

psi and is usually maintained by a supply and scav-

bearings through jets on the forward and aft sides of

enge pump (refer to scavenging in appendix C).

the bearing. The carbon seal runner for the bearing

Most systems include a heat exchanger to cool the

is cooled by oil which has lubricated the power take-

oil and an oil supply tank.

off unit and the compressor forward shaft, and is

b. On-engine components usually include lubri-

then sprayed outward through holes in the shaft.

cation supply and scavenge piping, a supply tem-

This oil is then passed through holes at the seal

perature RTD sensor (resistance temperature detec-

runner where an oil slinger moves it away from the

tor), and chip detectors at A, B, and/or C oil

carbon seal.

collection sumps. Nozzles are provided for oil distri-

3-31

|

|

|

|

||