Custom Search

|

|

|

||

TM 5-685/NAVFAC MO-912

APPENDIX G

DIESEL ENGINES: OPERATION, TIMING, AND TUNING INSTRUCTIONS

G-1. Starting and stopping.

and subsequent use when needed. An engine can be

damaged by improper shutdown or starting prac-

a. General. Starting and stopping procedures ap-

tices.

ply to diesel engines that are not equipped with an

automatic start and shutdown feature such as the

G-2. Engine timing.

manually operated engine used in a Class B system.

a. Timing function. The fuel injection system

The procedures may be used if an engine is to be

must be timed so that combustion starts at, or just

exercised. Instructions for the operator, including

before, piston top dead center (TDC).

operation and recording of instrument data, are

(1) Early ignition produces excessively high

provided.

cylinder pressures and detonation from the rapid

b. Starting. Before starting make sure engine an-

pressure rise. Late ignition occurs when the piston

cillary equipment is ready to function. The major

is moving away from the cylinder head, conse-

portion of normal wear occurs while starting a cold

quently the expansion ratio is reduced and effi-

engine or an engine which has been idle. Proper

ciency is lost. Another timing function is the rate of

starting technique includes inspection to verify that

injection, or the duration of the injection period.

the engine and its accessory plant are ready for

(2) Injection continues over a measurable pe-

operation, adequate fuel is available, and lubricat-

riod of time, usually expressed in degrees of crank-

ing oil, coolant and other supplies are at proper

shaft rotation. It is desirable to inject the fuel as

levels. Starting involves proper positioning of the

quickly as possible without creating high cylinder

engine, use of the starting system and proper accel-

pressures. The fuel burning period should be com-

eration to operating speed. Starting also includes

pleted within the 15-20 degrees of crankshaft rota-

application of the load to the engine.

tion after top dead center.

c. Operation. After engine operation starts and

(3) The time of start of injection is determined

the load is applied, operator duties include following

by ignition delay, since initial combustion must be

the load variations and making necessary opera-

secured by top dead center, or slightly before. Dura-

tional adjustments. The operator must continuously

tion of the injection period is determined by the

observe operation to determine deviations from nor-

allowable rate of pressure rise in the cylinder. If

mal or acceptable including ranges of operating

ignition delay is assumed to be .0025 second, the

following applies to high, medium and low speed

pressures, temperatures or other operational pa-

engines operating at 1,800,600 and 300 rpm respec-

rameters. Unusual sounds, smells, vibrations of os-

tively.

cillations of the engine and major variations in in-

strument readings, may indicate some abnormal

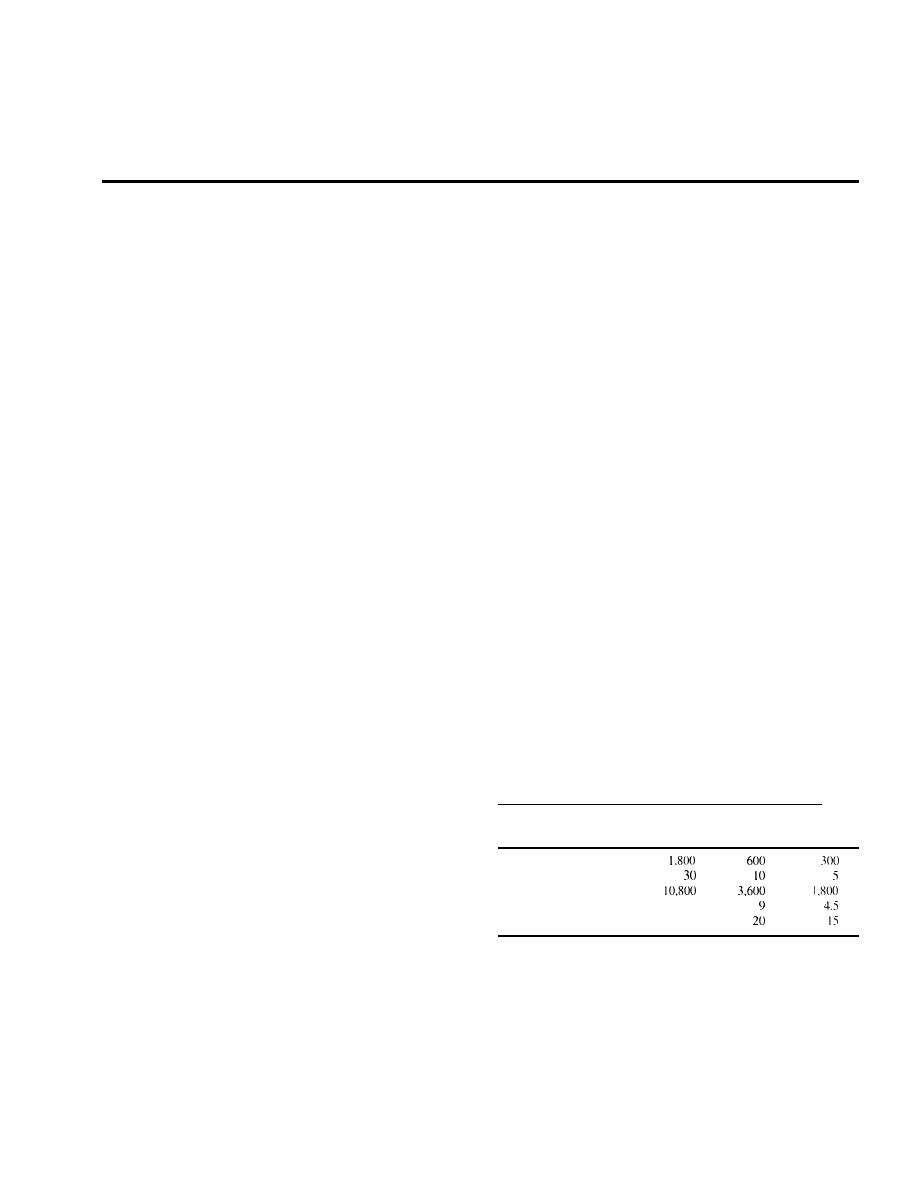

Table G-1. Ignition delay and duration.

condition.

-

-

d. Recording. Instrument readings and operator

ENGINE SPEED

observations must be recorded for analysis. These

Description

High

Medium

Low

data may indicate trends toward deterioration or

Engine RPM

need for adjustment. Entries on engine and related

Rcvolutions/second

logs must be at regular intervals and accurate.

Degrees/second

Ignition delay. degrees

27

e. Operational maintenance. The operator should

Probable duration, degrees

30

be alert to possible malfunctions or deviations dur-

ing operation. Operational adjustments such as

(4) Note that the high-speed engine would re-

pressure and temperature should be noted and re-

quire an injection start timing 27 to 30 degrees

corded, if unusual. Ancillary equipment must be

before top dead center, and that all fuel is in the

inspected during engine operation.

cylinder by 3 degrees after top dead center. Pressure

rise is rapid once ignition starts, because nearly all

f. Stopping. Proper technique in stopping the en-

of the fuel is in the cylinder. As speed is reduced, a

gine and shutting down the ancillary equipment is

later start of injection is possible. For the

necessary. Correct shutdown permits the engine to

speed engine, about half of the total fuel charge is in

cool without excessive distortion of parts or stresses

the cylinder when ignition occurs, but the balance of

being imposed. The engine will be ready for restart

the charge is injected into the burning portion.

G-1

|

|

|

|

||