| Tweet |

Custom Search

|

|

|

||

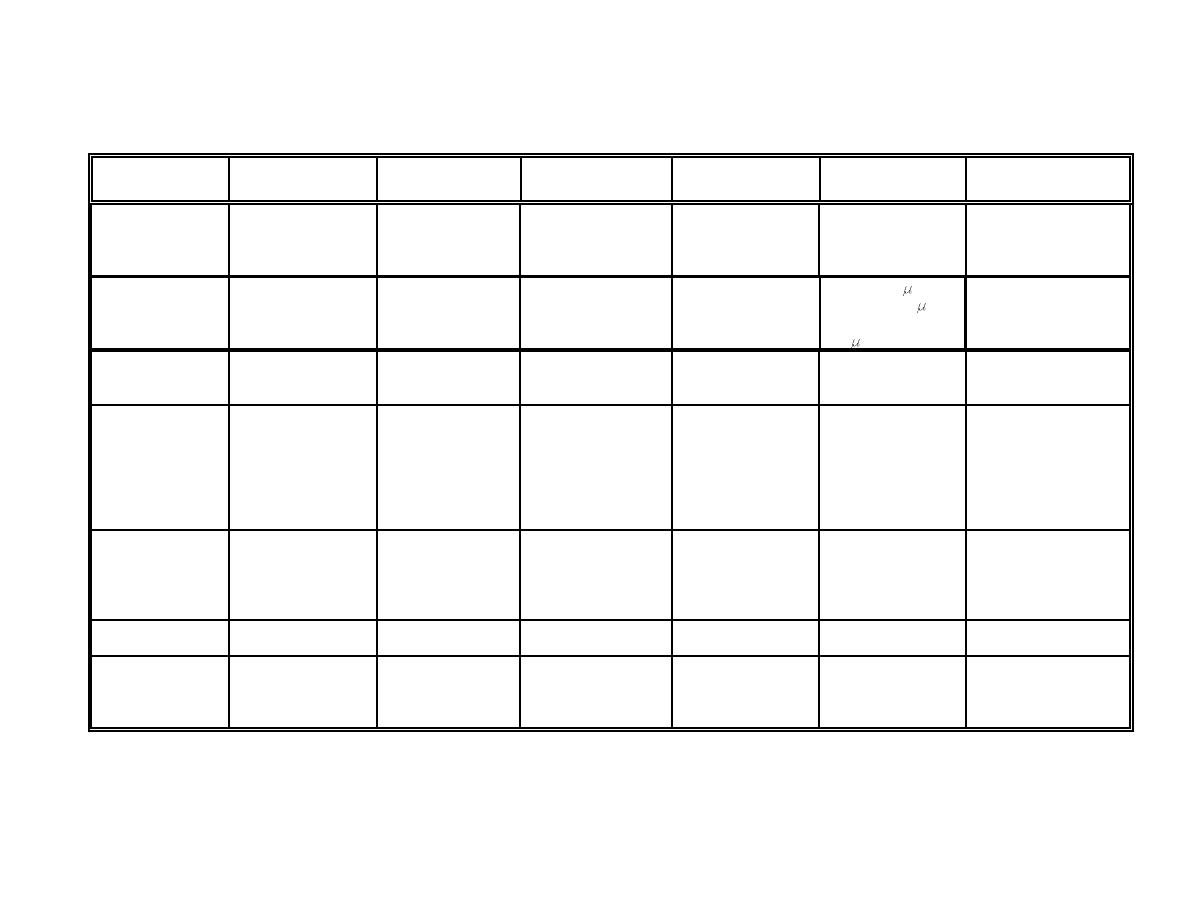

Table B-1. Air Sparging with Soil Vapor Extraction Site Characteristics

Site Name

Site Location

Soil Type

Depth to Water

Size of Site

Clean-up Level

Table

Present

Achieved

Oakland, CA

Silty sand, sandy clay

8-15 ft

500 ft x 500 ft;

BTEX; TPH;

Vapor concentrations

and gravel; Fine

15 ft BG

benzene

reduced from 11,000

grain organic silts

ppmv to below 1,000

and clays

ppmv in 8 months

Brunswick, Maine

Silty fine to medium

8 ft BG

150 ft horizontally

TPH gas(35 g/L)

Improving site

Building 538 NEX

sand

4-20 ft vertically

TPH fuel (460 g/L)

conditions (on-going)

Service Station

BTEX & MTBE (0-

5.3 g/L)

Cleveland, OH

Interfingered silt and

15-25 ft

BTEX

Site

silty clay; Sands and

TPH

sandy silt

Hydrocarbons

Silver Springs, Lyon

Loose clayey

36-38 ft

408 ft x 300 ft;

BTEX

Benzene decreased from

County, NV

sand/silt mixture;

38 ft BG

11,013 ppb to nondetect

Stiff, rhythmic

in 4 months; In 5

bedded clayey

months, 1842 gallons of

silt/silty clay; Dense

fuel extracted

to very dense, fine to

coarse, arkosick sand

2,000 ft2; 20-30 ft BG

Connecticut

Stratified sand and

19 ft.

TCE

Pilot test only; 4 lb

Electronic

gravel, fine sands and

DCA

contaminants removed in

Component

silts

TCA

4 weeks

Manufacturing

tetrachloroethane

Facility

carbon tetrachloride

Europe

Quaternary sand and

27 ft

TCE; PCE

99.18% total reduction

gravel, silty sands

of VOCs in 3 months

Sand, slit, clay

135 ft

330 ft BG

TCE; PCE

98-43.03% TCE

reduction

96.47-32.6% PCE

reduction

Table B-1. Air Sparging with Soil Vapor Extraction Site Characteristics (Continued)

|

|

|

|

||