| Tweet |

Custom Search

|

|

|

||

Crushing, Grinding and Screening Equipment

REBUILDING AND HARD-FACING CRUSHER

ROLL SHELLS

Initial Rebuild and Hard-face of Shells

To relieve stress before hard-facing, new Manganese

shells should be operated for a short period of time.

After this brief initial period, during which wear

should be limited to approximately 3/16 in., a regular

schedule of roll upkeep should be established. If rolls

are worn less than 3/1 6 in.. they can be hard-faced with

recommended alloys. If excessive wear has occurred,

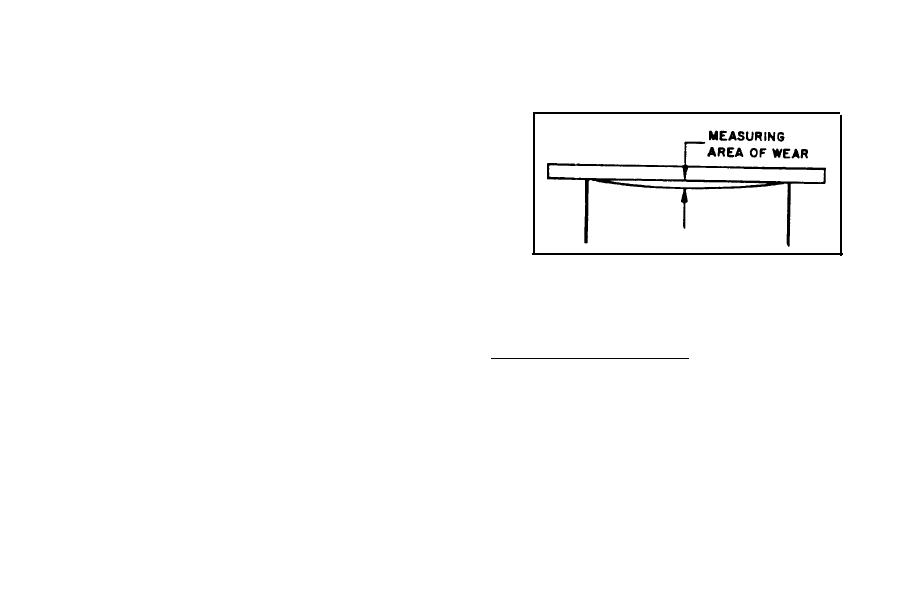

FIGURE 2-62. Wear Measurement

the worn rolls must be rebuilt to size and contour

of Crusher Roll Shells

before hard-facing. The amount of wear can be

measured (Figure 2-62).

General Recommendations

There are certain procedures that are common to roll

rebuilding whether welding is done manually,

semi-automatically or automatically; the success of the

rebuilding and hard-facing operation is as dependent

upon them as upon subsequent welding techniques.

2-67

|

|

|

|

||