| Tweet |

Custom Search

|

|

|

||

REBUILDING AND HARD-FACING CRUSHER

ROLL SHELLS (Continued)

When to Reapply Hard-facing

Additional hard-facing should be applied after 70-80

percent of the previous overlay has worn away, but

before the base metal is exposed. Hard-facing can be

repeated several times, depending on how much of the

previous overlay is allowed to wear away. Generally,

wear is uneven and eventually excessively thick hard

metal deposits on some areas of the roll may span.

When this occurs the roll should be allowed to wear

until all the hard metal is gone and the shell casting has

been worn 1/8 - 3/16 in. The roll can then be restored

to size with recommended buildup alloys. After

rebuilding the shell should be overlaid with a

wear-resistant alloy. If sufficient welding time is

available, all striping should be reapplied.

If time is limited, apply only every second or third

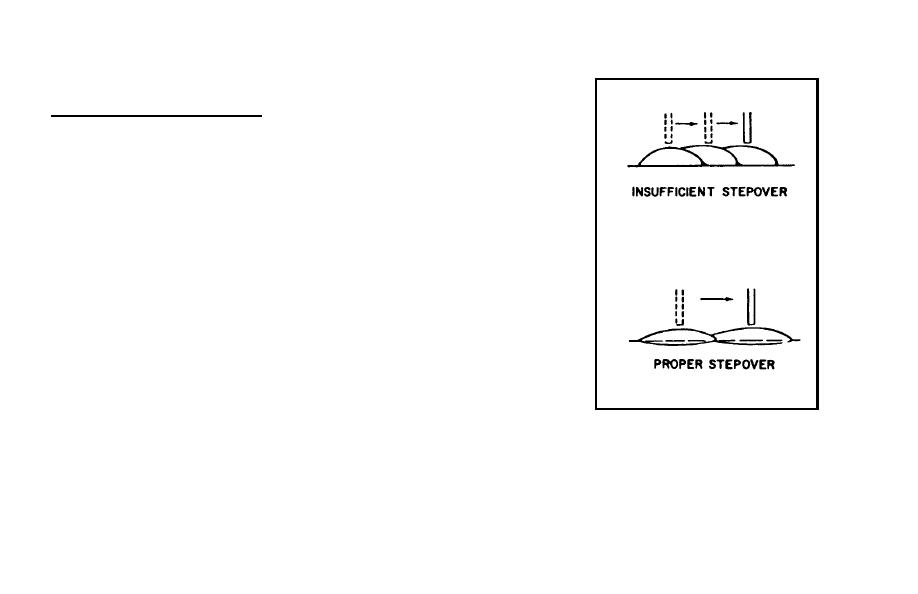

FIGURE 2-65. Insufficient and Proper Stepover

gripper bead. Do not apply more welding beads to one

Techniques Examples

side or section of the roll than another. This will put

the roll out of round, reduce sizing efficiency, and

accelerate wear on other crusher components.

2-71

|

|

|

|

||