Custom Search

|

|

|

||

TM 5-684/NAVFAC MO-200/AFJMAN 32-1082

c. Cleaning. Insulators in severely contaminated

b. Altitude derating. As altitude increases the in-

sulation value of air decreases, so that an insulator

atmospheres may require frequent cleaning. Pollut-

at a high elevation will flashover at a lower voltage

ant buildup increases operating stresses and in-

than the same insulator at sea level. The low fre-

creasing the flashover level will help compensate for

quency dry flashover value of an insulator at 7,000

this. Such an increase does not eliminate the need

feet (2,100 meters) is about 80 percent of the low

for cleaning insulators.

frequency dry flashover at 1,000 feet (300 meters).

Section XIII - GUYS

4-48. Guy functional requirements.

where. Copper-covered steel wire should be used

only where specifically justified to meet an environ-

Guys are used whenever the line wires would tend

mental requirement.

to pull the pole out of its normal position because of

b. Wire replacement. Rated breaking strength

unbalanced forces from dead-ended conductors,

used for replacement guys should not be less than

changing conductor sizes or material, or other con-

6,000 pounds (2,700 kilograms). Replacement guy-

ditions. The vertical forces of the line are resisted by

ing should always be engineered. Because of corro-

the pole, while the guy counteracts the unbalanced

sion or damage, the strength of existing guys on a

horizontal components.

pole may be less than for a new guy stranding of the

a. Inadequate guying. Inadequately guyed lines

same initially designed diameter. Existing guy

soon begin to sag, causing an unsightly installation,

strands may be overloaded, if it is assumed they

degrading line reliability, and possibly creating an

have the same strength as new strands. Guy

unsafe supporting structure because the pole is

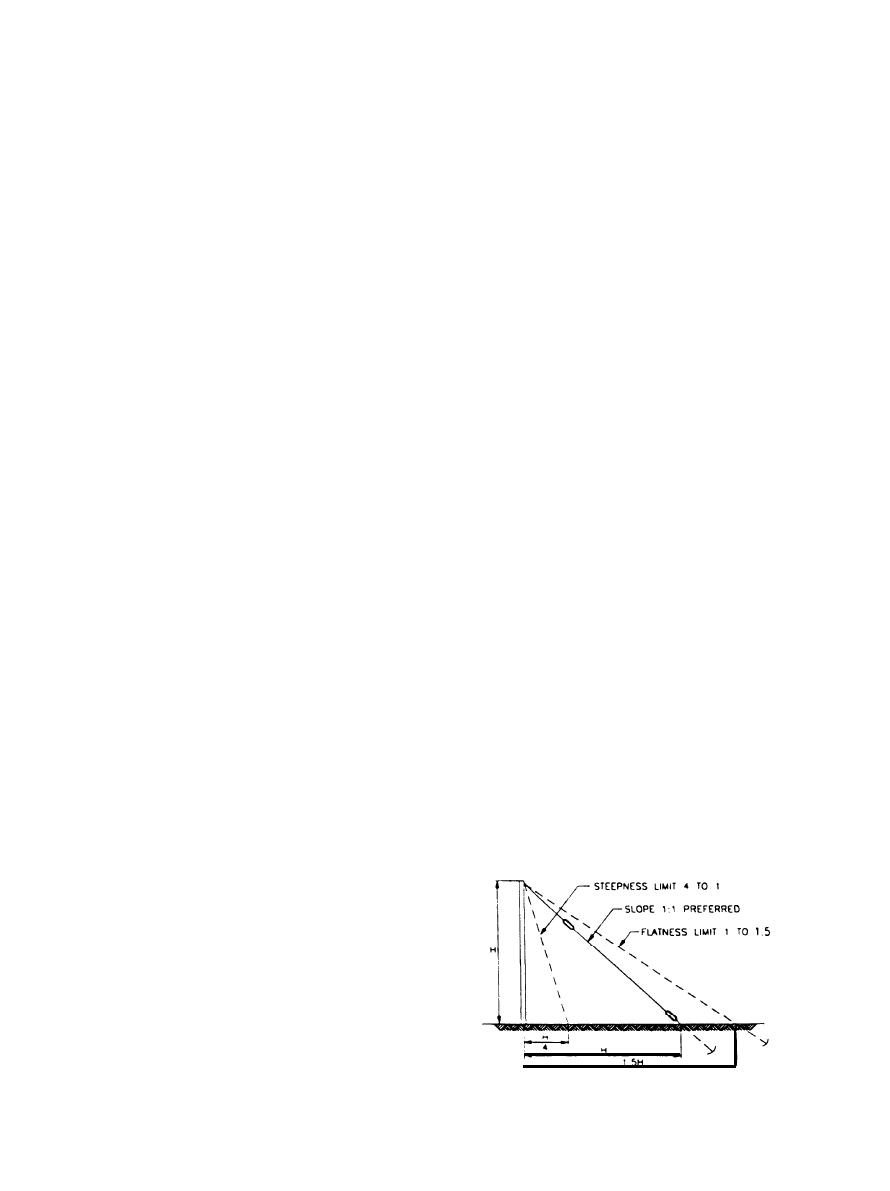

strands should not exceed the steepness and flat-

overloaded.

ness limits of figure 4-18. If these limits cannot be

maintained, then pole embedding may be necessary.

b. Guy components. Guy installations usually in-

clude the guy wire (strand), the anchor assembly,

4-50. Anchor assemblies.

attachments to poles and anchor rods from the guy

strand, strain insulators, and sometimes guy mark-

An anchor assembly with a rod and patent anchor

ers.

buried in the ground is normally used to hold down

the guy strand. Above-ground objects, such as trees

c. Replacements or modifications. When any guy

or buildings, have sometimes been used for tempo-

component becomes weakened due to corrosion or

rary guying, but only exceptional circumstances

physical damage, that component should be re-

should justify any such interim use. Once installed,

placed. Retension guy wires where any slack is ob-

assemblies seldom require any maintenance except

served. If a change is made in the number, size, or

for inspection of the anchor rod for corrosion near

location of conductors, guys should be added or

the ground line, where repair should be provided as

changed as required by the changed conditions.

needed. In soils with a resistivity less than 30,000

Guys should be checked whenever poles are

ohm-centimeters and where corrosion of under-

checked.

ground ferrous structures is a problem, galvanized

steel anchors and guys should not be connected to

4-49. Guy strand.

copper grounding systems because severe corrosion

The major component in each guy installation is the

may result. Instead, strain insulators need to be

guy strand or wire, whose rated breaking strength

installed in the guy wire. When replacing an assem

determines the requirements for all other compo-

nents.

a. Wire types. Wire of either three or seven

strands is commonly used. Each strand consists of a

steel core having a protective coating of zinc or

aluminum. Zinc coatings are available in standard

ASTM coating weights, and a Class A coating

weight is half of a Class B coating weight and a

third of a Class C coating weight. The coating

weight used is dependent upon atmospheric corro-

sion. Class A is used in dry or desert areas with

little industrial contamination; Class C (or alumi-

num) is used in salt-laden or foggy areas or heavily

contaminated locations; and Class B is used else-

Figure 4-18. Steepness and flatness limits for guy strands

4-25

|

|

|

|

||