Custom Search

|

|

|

||

MIL-HDBK-1013/12

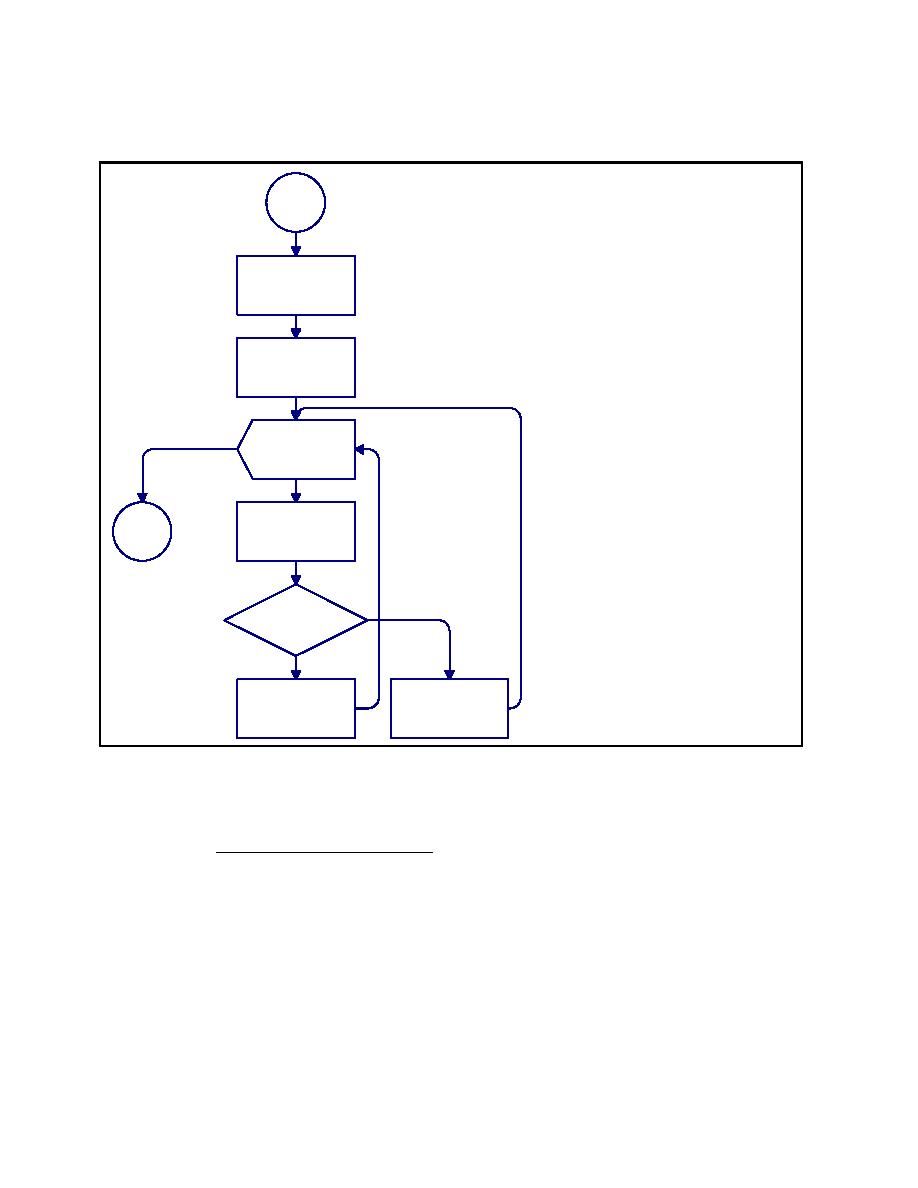

<1> Enter Glazing Dimensions. Enter

glazing height and width in inches

Start

into columns (b) and (c),

respectively, of the Safevue Data

Entry worksheet (see Appendix B

for all worksheets). Dimensions are

gasket center line to gasket center

<1> Enter Glazing

line. Glazing areas larger than 25

Dimensions

square feet are not recommended

for blast resistant windows.

Proceed to <2>.

<2> Enter Bite. Enter depth of bite in

inches into column (d) of the

<2> Enter Bite

Safevue Data Entry worksheet.

Proceed to <3>.

<3> For Each Plate: For each plate in

cross-section, do <4> through <7>.

<3> For Each

Done

When done, return to Figure C-2.

<4> Enter Type of Glazing Material.

Plate:

Enter glazing material type in

Next

column (a) of the Safevue Analysis

worksheet. Proceed to <5>.

<5> Is Material Glass? If material is

<4> Enter Type of

Stop

glass, proceed to <6>. Otherwise,

Glazing Material

proceed to <7>.

<6> Enter Layer Thicknesses. Enter a

series of thicknesses for glass

<5> Is

layers into the layer fields of column

Yes

(b) of the Safevue Analysis

Material Glass?

worksheet. Start with layer field 1.

Proceed to <7>.

No

<7> Enter Total Thickness of Plate.

Enter the total thickness of a plate

in inches into column (c) of the

<7> Enter Total

<6> Enter Layer

Safevue Analysis worksheet.

Thickness of Plate

Thicknesses

Proceed to <3> for next plate.

Figure C-3

Process Chart and Description: Glazing Data Preparation for Evaluation

Analysis Procedure

C.4.1

Required Information. The following information is

required for data preparation for an evaluation analysis:

a) Glazing height, gasket center line to gasket center

line

b) Glazing width, gasket center line to gasket center

line

c) Bite depth

d) Number of stacked plates in cross-section

e) For each stacked plate:

121

|

|

|

|

||