| Tweet |

Custom Search

|

|

|

||

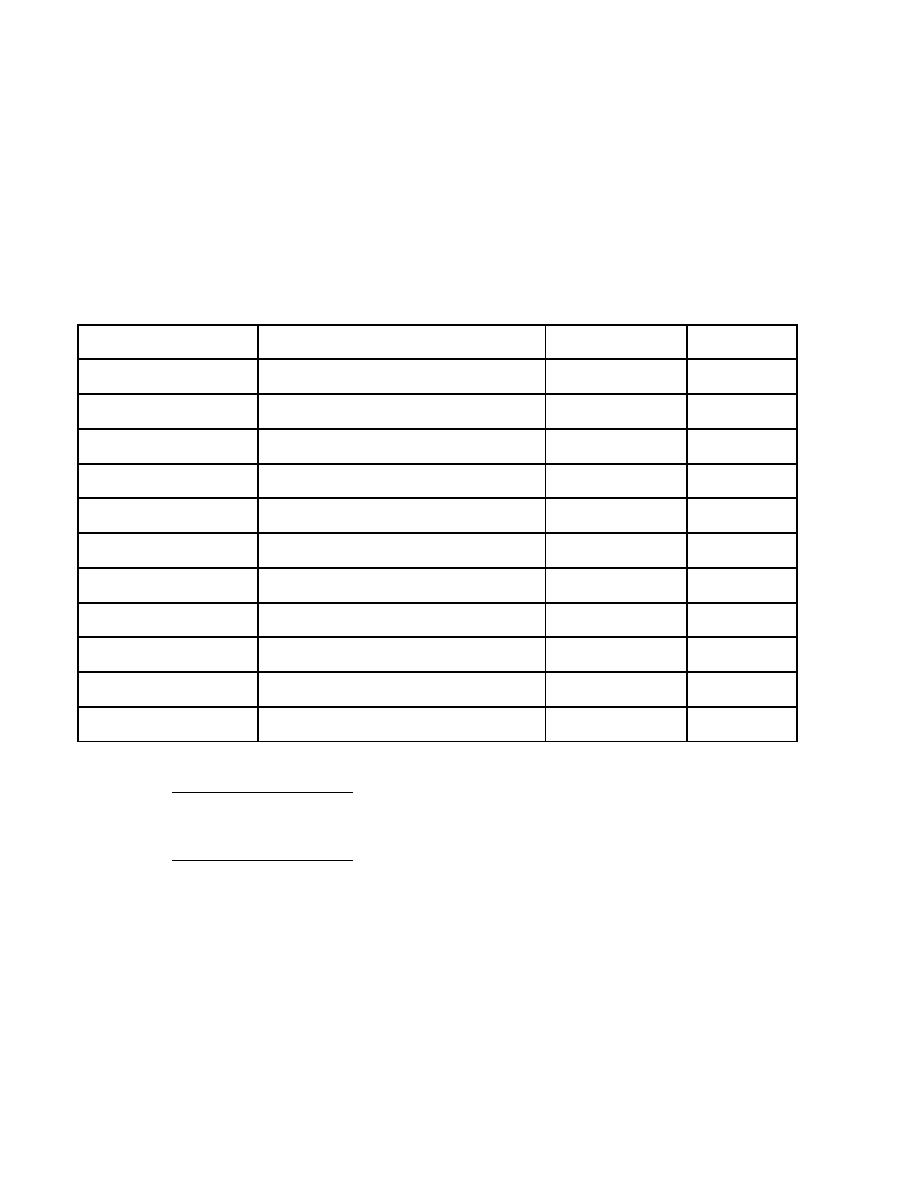

MIL-HDBK-1038

impractical. Except for standard commercial gear reducers, there are no industry

standards for bearing selection for cranes. The criteria listed in Table 2 have

been established by NCC and are mandatory for new crane designs. The L-10 life is

calculated for the speed (RPM) of the bearing at its location in the drive train

or system when the drive motor is operating at the rated speed of the drive. For

reeving systems, the speed of the lead sheave is used for all sheaves in the

system.

Table 2

Bearing Life Determination Criteria

Crane Type

Drive

L-10 Life

% Maximum

(Hours)

Load

Portal and

Main Hoist, including sheaves

5,000

75

Floating

and hook block

Portal and

Auxiliary hoist, including

7,000

75

Floating

sheaves and hook block

Portal and

Whip hoist, including sheaves

8,000

75

Floating

and hook assembly

Portal and

Luffing hoist, including

5,000

75

Floating

sheaves

Portal and

Rotate, excluding the rotate

7,000

85

Floating

bearing

Portal

Travel, including axles

10,000

85

Container

Hoist, including sheaves

25,000

75

Container

Boom hoist, including sheaves

15,000

75

Container

Trolley, including axles

25,000

75

Container

Travel, including axles

15,000

100

Container

Re-reeving devices

15,000

75

5.3.6.2

Hook Thrust Bearings. Hook thrust bearings are selected on the basis of

the published static rating, which must be at least 50 percent greater than the

hoist rating.

5.3.6.3

Bearing Installation. Bearings are installed with a press fit at one of

the races, usually the rotating race. The fit tolerances are published by the

bearing manufacturers, and must be followed. When adequate space is available,

bearings may also be mounted over a tapered slotted sleeve interposed between the

bearing inner race and the shaft. The sleeve is threaded on the smaller end for a

tightening nut that bears against the face of the inner race and pulls the sleeve

into the bearing inner race to obtain the desired press fit. The sleeve, its

tightening nut, and the inner race are furnished as a matched assembly by the

bearing manufacturer. The tightening nut must be installed per the bearing

manufacturer's directions and locked with a tab washer against loosening. For

light service, such as bridge drive shaft support, bearing inner races may be

secured to the shaft with a set screw. The inner race and the shaft are selected

for a loose fit.

148

|

|

|

|

||