Custom Search

|

|

|

||

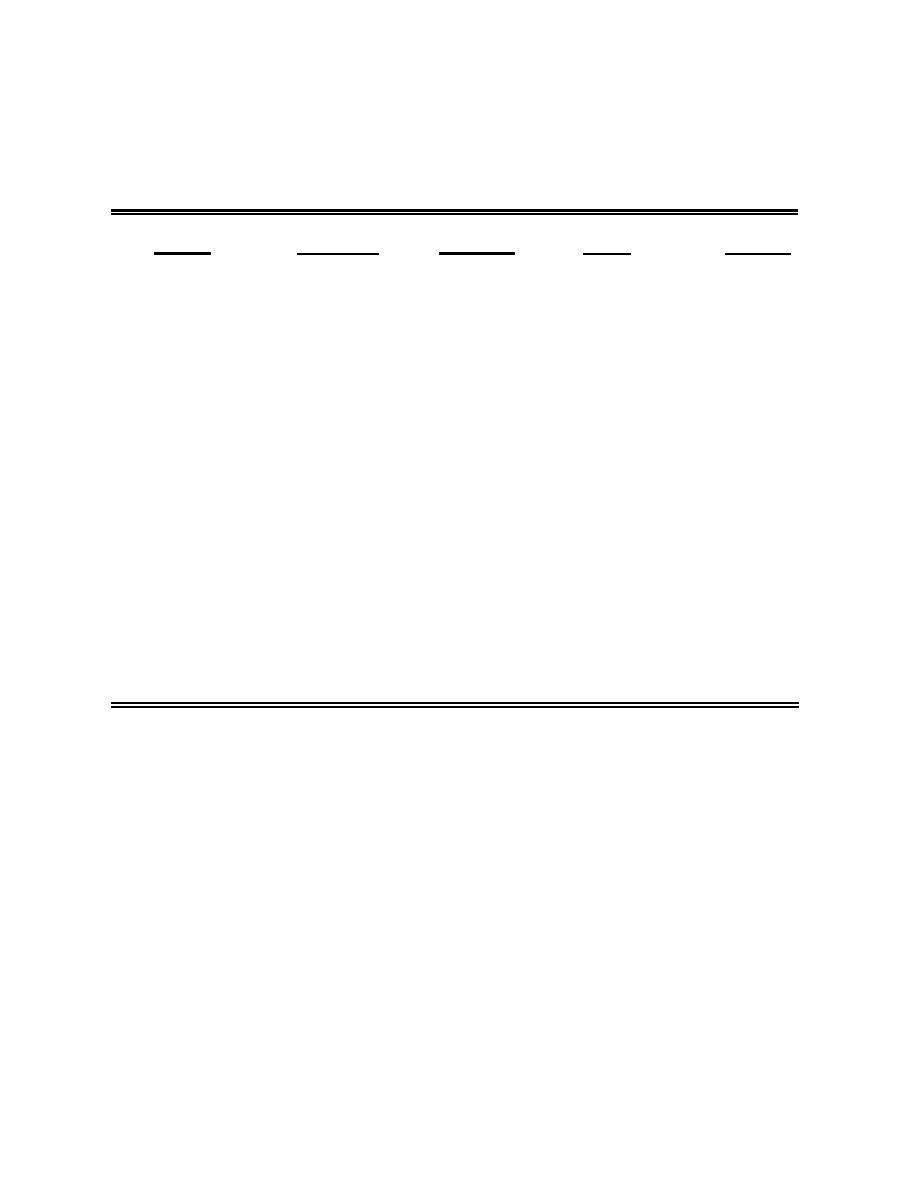

MIL-HDBK-419A

Table 1-23

Minimum Torque Requirements for Bolted Bonds

Bolt Size

Min. Torque

Tension

Threads/Inch

Bond Area

(in -1bs)

(in.2)

(lbs)

32

18

625

0.416

#8

36

20

685

0.456

#10

24

23

705

0.470

32

32

940

0.626

1/4"

20

80

1840

1.225

28

100

2200

1.470

5/16"

18

140

2540

1.690

20

150

2620

1.750

16

250

3740

3/8"

2.430

24

275

3950

2.640

7/16"

14

400

5110

3.400

20

425

5120

3.420

1/2"

13

550

6110

4.070

20

6140

575

4.090

5/8"

11

920

7350

4.900

3/4"

10

1400

9300

6.200

7/8"

9

1950

11100

7.400

1"

8

2580

12900

8.600

f.

Once the mating surfaces have been cleaned of all nonconductive material, join the bond members

together as soon as possible. If delays beyond two hours are necessary in corrosive environments, the cleaned

surfaces must be protected -with an appropriate coating which, of course, must be removed before completing

the bond.

Alligator clips and other spring loaded clamps are to be employed only as temporary bonds. Use

g.

them primarily to insure that personnel are not inadvertently exposed to hazardous voltages when performing

repair work on equipment or on facility wiring.

1-141

|

|

|

|

||