Custom Search

|

|

|

||

MIL-HDBK-419A

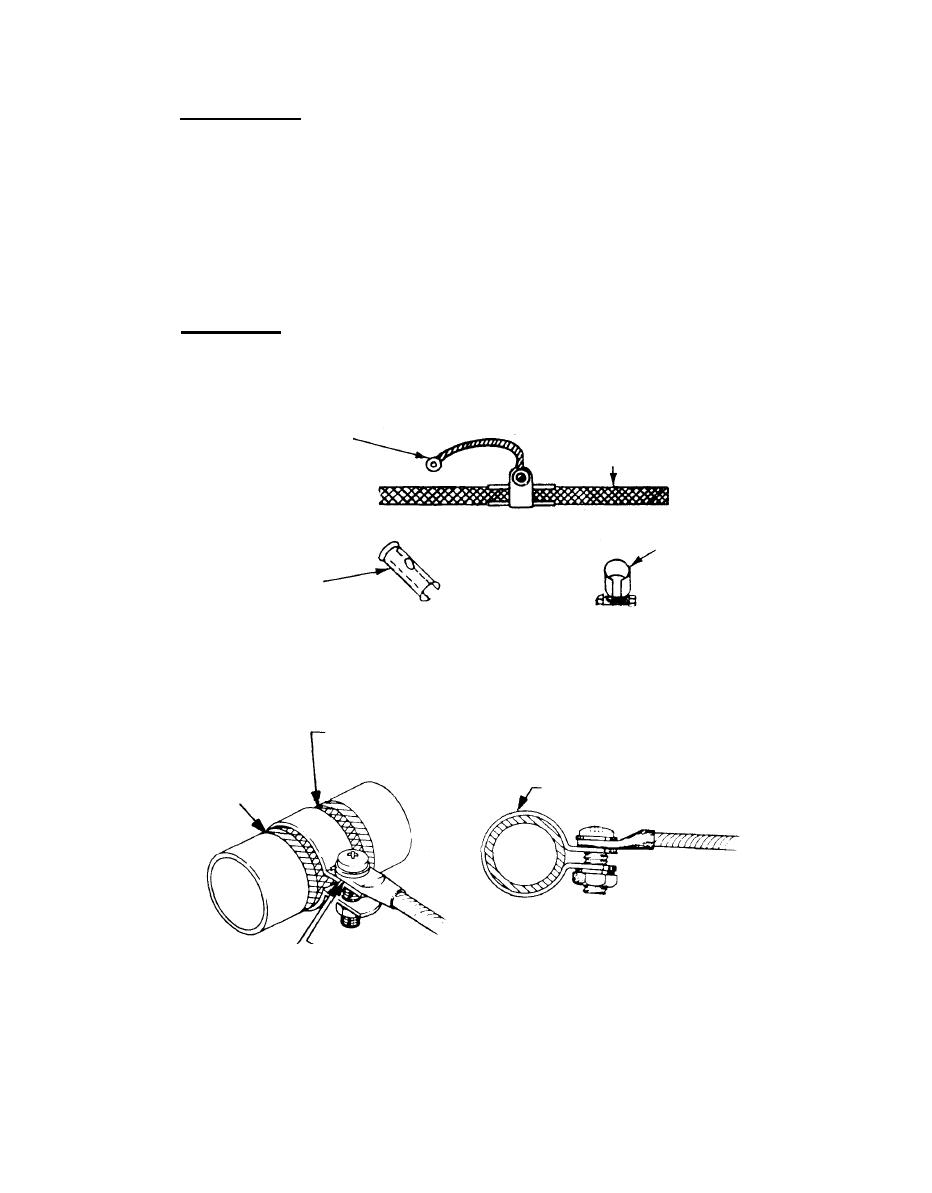

1.7.4.2 Tubing and Conduit. Long spans of conduit should be properly bonded to the structure at both ends and

at several intermediate points. Ordinary clamps cannot be used to bond flexible conduit since the required

pressure on a comparatively small surface area may be sufficiently high to compress or collapse the conduit.

Instead of ordinary clamps, use a flared, split sleeve (Figure 1-73) fitted around the flexible conduit. This

sleeve distributes the high pressure of the bonding clamp over a large area, thereby exerting low pressure on the

conduit. Figure 1-74 illustrates a method for bonding to rigid conduit. With either type of clamp, the conduit

or tubing should be cleansed of paint and foreign material over the entire surface covered by the clamps. All

insulating finishes should be removed from the contact area before assembly, and anodized screws, nuts, and

washers should not be used to attach contacting parts.

1.7.4.3 Other Examples. Figures 1-75 through 1-80 illustrate recommended bonding methods appropriate for

most facilities.

BOND STRAP

FLEXIBLE TUBE

CLAMP

SLEEVE

Figure 1-73. Bonding to Flexible Cable and Conduit

CLEAN TO BASE METAL

INSIDE OF CLAMP AND

TO 1 CLAMP WIDTH

REFINISH AFTER INSTL.

CLAMP (MATERIAL: AS APPLICABLE TO TUBE)

1 DIA CLEANED AREA

BONDING OR CURRENT

RETURN JUMPER

CLEAN AREA OF CLAMP TAB THAT

SEAL AFTER INSTL

1 DIA CLEANED

TOUCHES TERMINAL TO BASIC

AREA

METAL

Figure 1-74. Bonding to Rigid Conduit

1-149

|

|

|

|

||