Custom Search

|

|

|

||

TM 5-683/NAVFAC MO-116/AFJMAN 32-1083

lamp voltage as well as for changes in the line

voltage. The operating voltage of an HPS lamp can

change as much as 60 percent as it ages and the

ballast operating characteristics throughout the life

of the lamp is the key to good system performance.

High pressure sodium. is more efficient than mer-

cury or metal halide lamps.

d. Low pressure sodium (LPS) lamps. The LPS

lamps are physically and electrically similar to fluo

rescent lamps but without the phosphor coating. A

ballast is required to start the LPS lamp. There is

about a 10-minute warm-up period when the lamp

is first turned on. LPS lamps are larger than mer-

cury, metal halide and HPS lamps. The largest LPS

lamp is 180 watts, 44 inches long and emits 33,000

lumens of yellow (monochromatic) light compared to

a 400-watt HPS lamp 10 inches long which emits

50,000 lumens. There are about 1000 milligrams of

sodium in the 180-watt LPS lamp compared to 6

milligrams of sodium in the 400-watt HPS lamp.

Because of this, LPS lamps require special disposal

precautions that do not apply to HPS lamps. Appli-

cations for LPS lamps are limited to roadways or

floodlighting where color rendition is not important.

(1) Installation. A suitable ballast must be used.

The ballast must be in compliance with Illuminating

Engineer Society (IES) and/or ANSI specifications- If

using power factor correction in a star connected

multi-phase distribution, the power factor correcting

capacitor should be connected between the line and

neutral. A filter coil must be used if there is audio-

frequency switching signals on the mains. The lamp

should be installed within the indicated limits to

avoid accumulation of sodium in the arc tube. Accu-

mulation of sodium could reduce lamp life. Lamps of

90 watts or more must be set within 20 degrees of

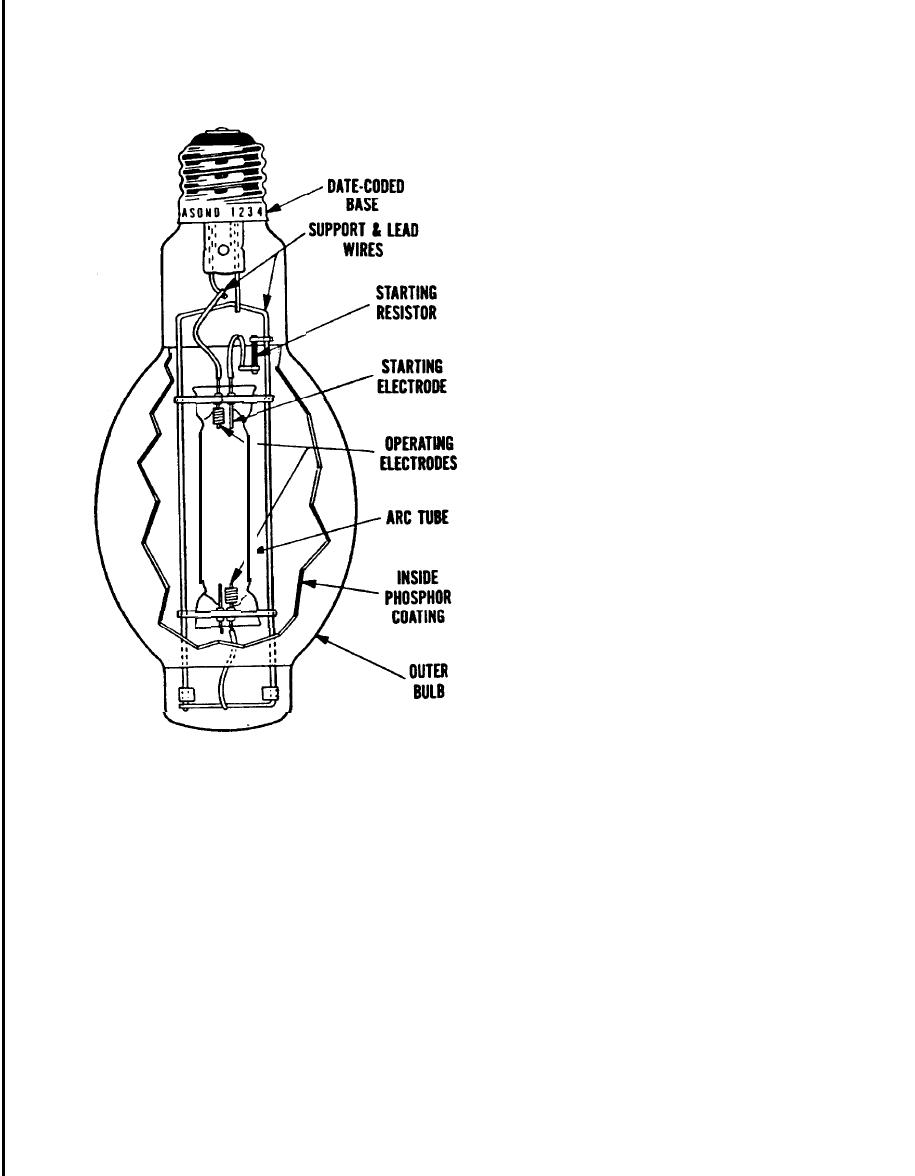

Figure 9-2. Mercury lamp.

horizontal. Lamps of 55 watts or less may operate up

to 20 degrees above horizontal.

b. Metal halide lamps. Metal halide lamps re-

(2) Maintenance. Do not allow the lamp to be

semble mercury lamps in appearance and are used

scratched. Ensure that power is off before installing

similarly. The color produced is better than mercury

or removing the bulb. To avoid electric shock do not

lamps and control of the light is easier. The initial

touch any metal parts of a broken bulb. A great

efficiency is also better for wattages above 150W.

degree of heat is produced by contact of the sodium

Otherwise mercury lighting is more efficient. Disad-

with a small amount of water. Therefore the lamps

vantages of metal halide lamps are a higher cost,

must be stored or carried in their original container.

and a shorter life expectancy than mercury lamps.

(3) Disposal. Let the lamp cool before removal.

c. High pressure sodium (HPS) lamps. The HPS

To avoid the danger of fire or broken glass, care

lamp package is similar to the mercury vapor lamp.

must be taken in handling discarded lamps. No

Like most discharge lamps, the operating voltage is

more than 20 lamps at one time should be broken

not compatible with supply voltage and a current

into small pieces in a dry container of adequate size

limiting ballast must be used. The HPS ballast

and in an open area. To avoid injury from flying

must compensate for both variations in line voltage

glass, goggles should be worn. The broken pieces

and lamp voltage change due to ageing process in

should be sprayed with water from a distance.

the tube. The mercury lamp operating voltage

When the chemical reaction has ceased the sodium

is harmless and the broken glass should be disposed

changes very little with life. With the HPS lamp,

of as normal waste.

the ballast must compensate for changes in the

9-3

|

|

|

|

||