Custom Search

|

|

|

||

TM 5-683/NAVFAC MO-116/AFJMAN 32-1083

faces that cannot be adequately cleaned and pol-

9-5. Cleaning.

ished should be replaced.

The cleaning schedule should be coupled with

relamping (spot/group schedule to minimize labor

9-6. Relamping.

costs). The cost of cleaning versus replacement

The longer a lamp remains in service, the less light

should be carefully evaluated. It is well-known that

it produces. The different types of lamps-filament,

dirt absorbs and masks light. The progressive de-

fluorescent or high intensity discharge-depreciate

crease of light caused by accumulating dirt renders

at different rates. Since their life expectancy is also

periodic cleaning of lighting equipment-lamps, re-

different, replacement intervals will vary. The two

flectors and lens--a necessity. The frequency of

general relamping procedures are spot relamping

cleaning depends entirely upon local conditions.

and group relamping.

Fixtures in air-conditioned and air-filtered rooms

a. Spot relamping. Spot relamping is the replace-

may require cleaning only once a year. But in an

ment of individual lamps as they fail. Lamps that

atmosphere which is heavy with dust and fumes,

are blackened or discolored should also be replaced

cleaning every few weeks may be necessary. The

even if they are still b urning because this discolora-

cleaning intervals for a particular installation

tion indicates that the lamp will soon fail. Fluores-

should be determined by light meter readings after

cent lamps should be replaced as soon as they begin

the initial cleaning. When subsequent foot-candle

to flicker, or when the ends of the tube adjacent to

readings have dropped 15-20 percent, the fixtures

the base blacken (fig 9-3).

should be cleaned again. Readings should be made

b. Group relamping. Group relamping is most ap-

with the light meter at the working surface with the

plicable to fluorescent lighting. When relamping, it is

meter reader in the position of the operator or per-

economical to wash the fixtures. It is also advanta-

geous to inspect the sockets, hangers, reflectors and

son using the working surface. Lighting equipment

lens for broken glass, loose mountings, etc. Refer to

should be washed, not just wiped with a dry cloth.

the lamp manufacturer for recommended replace-

Washing reclaims five to ten percent more light

ment intervals and relamping procedures. It should

then dry wiping and reduces the possibility of mar-

also be noted that replacement lamps must be of the

ring or scratching the reflecting surfaces of the fix-

same type, color, wattage and voltage as those being

tures. Glassware, reflectors and diffusing louvers

replaced. The following procedures apply:

that can be removed should be cleaned as follows:

a. Immerse in the washing solution. Do not im-

merse lamp base or electrical connections in the

cleaning solution. Scrub with a soft brush or sponge.

When incrustation is not removed by scrubbing, use

No. 0 steel wool to remove dirt film.

b. Rinse in warm clear water and dry with a

clean cloth. Walls, ceilings and surroundings are an

important part of the overall illumination system

since they redirect light to the working area. The

most efficient lighting system is obtained when the

fixtures are new and when the walls, ceilings, floors

and furnishings of the room are clean and colored

with a high reflectance color. A lighting mainte-

nance program must therefore include cleaning and

painting of the walls and ceilings in addition to the

fixture cleaning schedule. Glassware, reflectors and

diffusing louvers that cannot be removed should be

cleaned as follows:

(1) Wipe with a moist cloth or sponge. When

0

incrustation is not removed by sponging, use No. 0

a

steel wool to remove dirt film. Care should be taken

to ensure that shreds of steel wool do not touch the

pin contacts or get into the lamp socket.

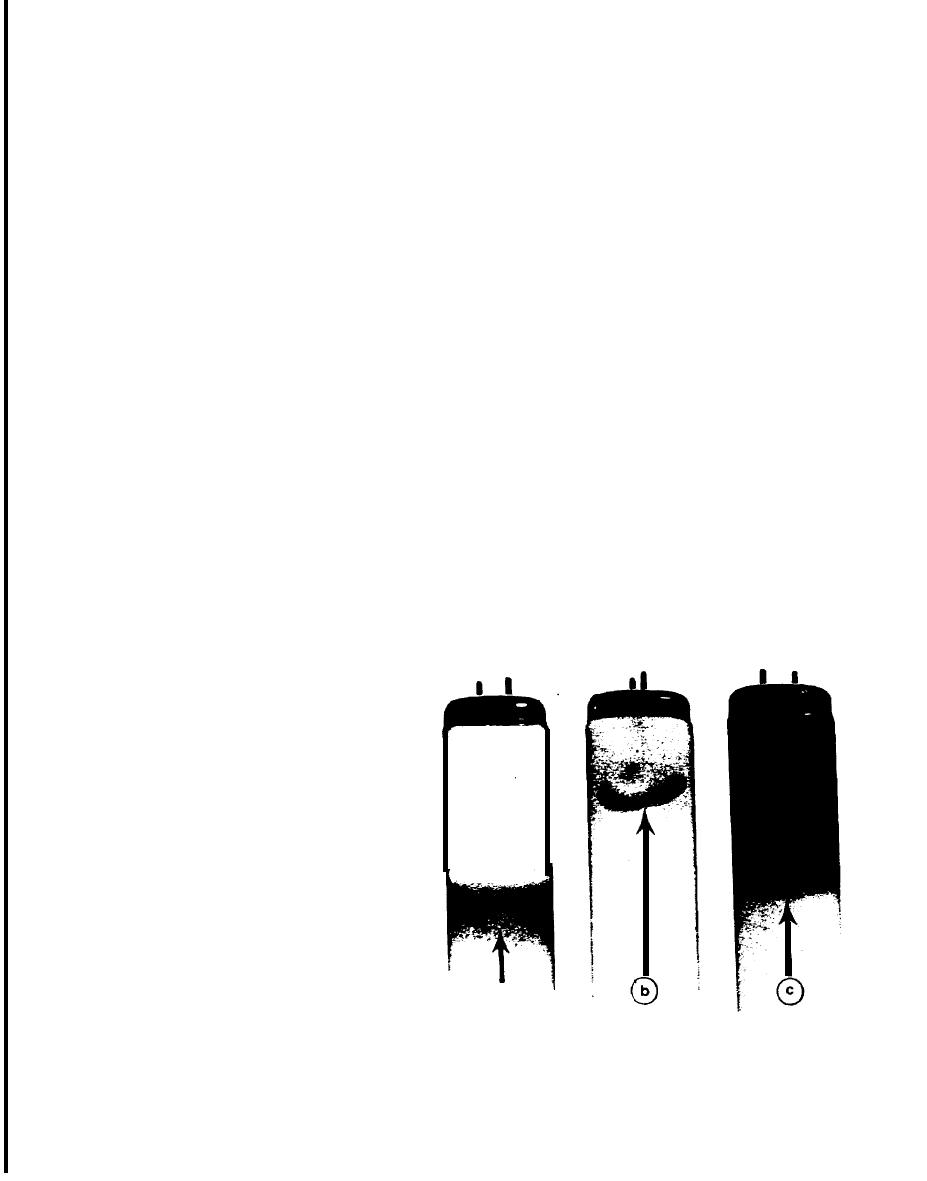

Figure 9-3. Trouble-Shooting Fluorescent Lighting: a) Grey or

(2) Wipe off excess moisture with a clean cloth.

brown bands 1"--2" from base are normal and do not affect useful

Clean fixture holders and stem hangers with a

life, b) Dark spots caused by condensed Mercury. Usually disap-

moist sponge or cloth and wipe dry. Enameled,

pear after lamp warms up, c) Large blackened areas at ends mean

chrome, aluminum or silver-plated reflecting sur-

lamp is at end of useful life.

9-4

|

|

|

|

||