Custom Search

|

|

|

||

TM 5-684/NAVFAC MO-2OO/AFJMAN 32-1082

conducting rubber or metallic foil or braid collar

around the porcelain under the first top skirts; con-

necting the collar to the test cable guard circuit;

grounding the mounting flange; and applying test

voltage to the central conduct of the bushing. The

collar should be of a type specifically designed for

bushing collar tests. Figure 3-2 shows connections

for hot- and cold-collar tests.

(1) Hot-collar test. This test is performed by

grounding the central conductor and the mounting

flange and applying test voltage to the collar on the

bushing. When hot-collar losses are found to be high

because of high relative humidity creating surface

leakage, the bushing should be cleaned. Furniture

or floor wax should be applied with a clean lintless

cloth. The wax should dry for 5 minutes and then be

rubbed briskly with a clean cloth to obtain a high

polish.

(2) Cold-collar test. This test is performed by

grounding the collar and mounting flange and ap-

plying test voltage to the central conductor of the

bushing. The difference between the overall watt

loss and the cold-collar loss is known as watts dif-

ference. In general, there appears to be no advan-

tage in the cold-collar test. The hot-collar test is

recommended.

j. Interpretation of power factor test results. The

--

limiting value at which different test operators re-

move bushings from service ranges from 6 to 12

percent power factor on bulk-type bushings and

from 2 to 6 percent on plastic and oil-filled bush-

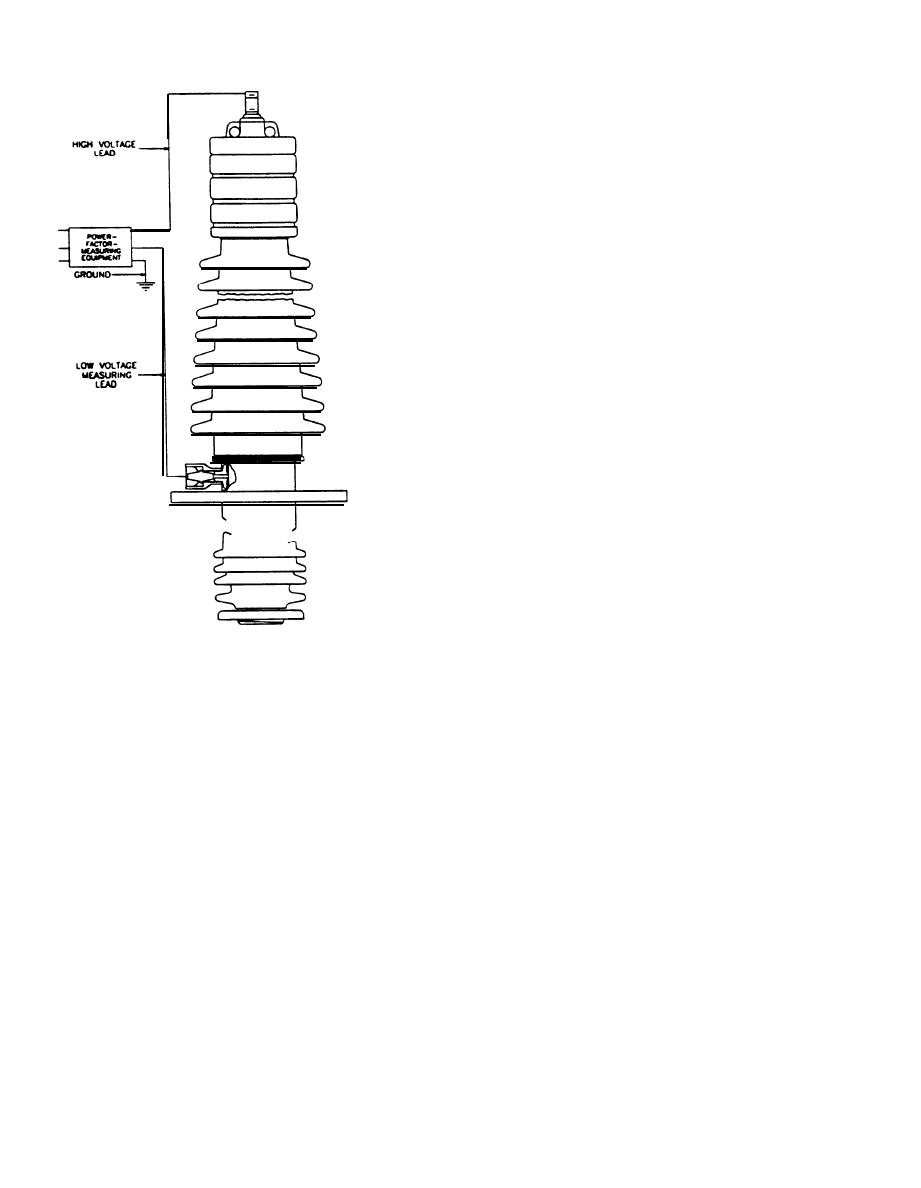

Figure 3-l. Connections for ungrounded specimen power

ings. These ranges are based on bushing tempera-

factor test

tures of 68 degrees F (20 degrees C), the power

(3) Connect the high-voltage lead of the power fac-

factor values being higher at higher temperatures.

tor test set to the top terminal of the bushing and the

Because the measurement of power factor is highly

low-voltage lead to the bushing support.

specialized and power factor values vary with differ-

(4) Ground the test set to the apparatus tank, and

ent types and makes of equipment, the procedure

measure the power factor

following such tests should be based on the recom-

(5) Record temperature of the bushing.

mendation of the qualified persons engaged to per-

h. High-voltage cold-guard circuit test. When

form the tests.

bushings to be tested have detachable cable conduc-

tors, they may be tested in the following manner:

3-35. Bushing insulation resistance test.

(1) Remove the bushing terminal and insulate

Insulation resistance tests measure insulation

the conductor from the bushing tube by stuffing a

losses by applying a dc voltage. This test is not so

small amount of insulation into the space between

widely used as the ac power factor test for bushings;

them. If bushing is equipped with an insulating

but, in the absence of facilities to test power factor,

head, it is only necessary to remove the connector

insulation resistance tests on bushings may prove

between the upper and lower rings.

useful.

(2) Clean the porcelain ring of the insulating

a. Procedures. The general procedure for insula-

head.

tion resistance testing is described in chapter 5,

(3) Connect the guard circuit to the cable lead

section VII. The following paragraphs contain spe-

and the high-voltage lead of the test set to the bush-

cific details for testing bushings.

ing tube.

b. Test values. See table 3-4 for requirements for

(4) Ground the mounting flange of the bushing.

insulation test values. Resistance readings should

i. Collar tests. The overall power factor test on

be carefully compared in one or two ways.

bushings may be performed by placing a flexible

3-12

|

|

|

|

||