Custom Search

|

|

|

||

TM 5-684/NAVFAC MO-200/AFJMAN 32-1082

441. Overhead line conductor splices.

not be salvaged. A compression connector may be

used only for the size of conductor for which it is

A splice is generally considered to be an end-to-end

made. Neither the connector nor the conductor

connection. It must be able to transmit the maxi-

should be altered to fit a conductor for which the

mum electrical load without undue heating and

connector was not designed. Several types of com-

should usually develop the full mechanical strength

pression sleeve splices are available:

of the conductors. Because of different characteris-

(1) Single sleeve. This splice is used for copper,

tics of copper and aluminum, connectors must be

suitable for the specific materials of the conductors

copper-clad, aluminum, and aluminum-clad conduc-

joined. Materials such as fluxes, inhibitors, and

tors, as shown in figure 4-12. A sealant port and set

compounds should be of a type which will not ad-

screw or plug is provided for injecting filler paste

versely affect the conductors. See chapter 1, section

before compressing the splicing sleeve with a

III. Compression and automatic-type splices cor-

hydraulically-powered compression tool. Some con-

rectly join together conductors in tension and pro-

nectors may have a factory-applied sealant.

vide the strength and electrical conductivity re-

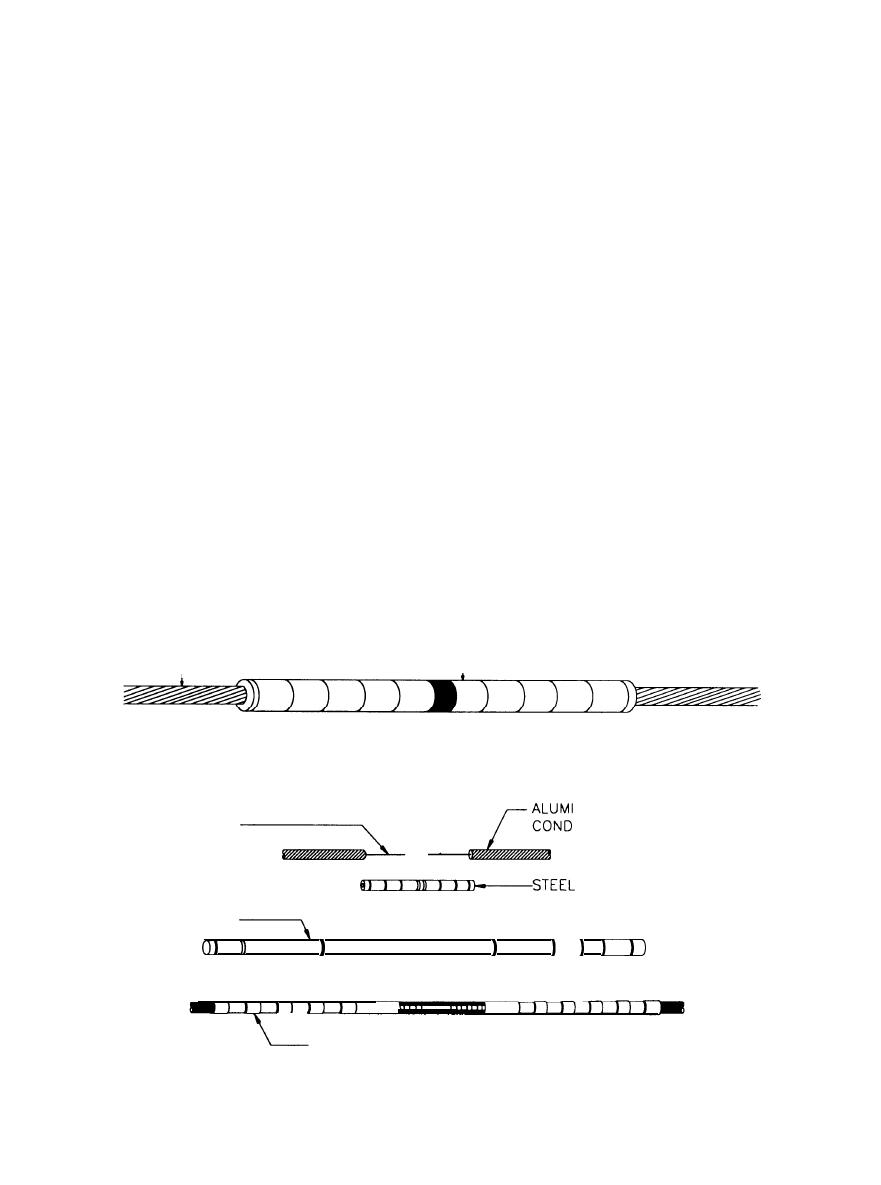

(2) Double-sleeue. This splice is used for ACSR

quired. Twist sleeve splices are no longer in use

conductors. In this type a steel sleeve is used to join

because they do not develop the strength of other

the steel support stand, and an aluminum sleeve is

connectors. Implosive-compression connectors are

used to join the aluminum conductors, as shown in

not recommended for use by facility personnel, as

figure 4-13. Both sleeves need to be compressed,

special training is required. Conductor connections

and the aluminum strands need to be cut back from

should be kept to a minimum. Keep splices in

the steel core.

transmission-line conductors at least 50 feet (15

(3) Single-sleeve and internal gripping unit.

meters) or more from dead-end connections. Do not

This splice is used for ACSR. A gripping unit pro-

make splices in lines crossing over railroads, rivers,

vides continuity for the steel core of the conductors

canals, or freeways. Also try to avoid splices in

being spliced and provides the required strength for

spans crossing over communications circuits or elec-

the tension applied. The splice requires only one die

tric transmission and distribution lines.

a. Compression sleeve splice. Compression sleeves

in the compression tool, as the gripping unit re-

provide full strength and conductivity and will pro-

places the double-sleeve's inner sleeve compressed

duce the most trouble-free connection, but they can-

on the steel core.

r

r

CONDUCTOR

SLEEVE

Figure 4-12. Single-sleeve compression splice (Courtesy of BURNDY Electrical)

STEEL SUPPORT

NUM

STRAND

UCTOR

SLEEVE

ALUMINUM

SLEEVE

D

D

DD

VIEW AFTER INSTALLATION

Figure 4-13. Double-sleeve compression splice (Courtesy of BURNDY Electrical)

4-19

|

|

|

|

||