Custom Search

|

|

|

||

TM 5-684/NAVFAC MO-200/AFJMAN 32-1082

4-42. Overhead line connections.

(4) Secondary and service cables. Secondary

and service cables can be spliced with bare or insu-

Tap, jump, loop and secondary dead-end connec-

lated compression connectors in a similar manner.

tions are generally considered to be tee connections.

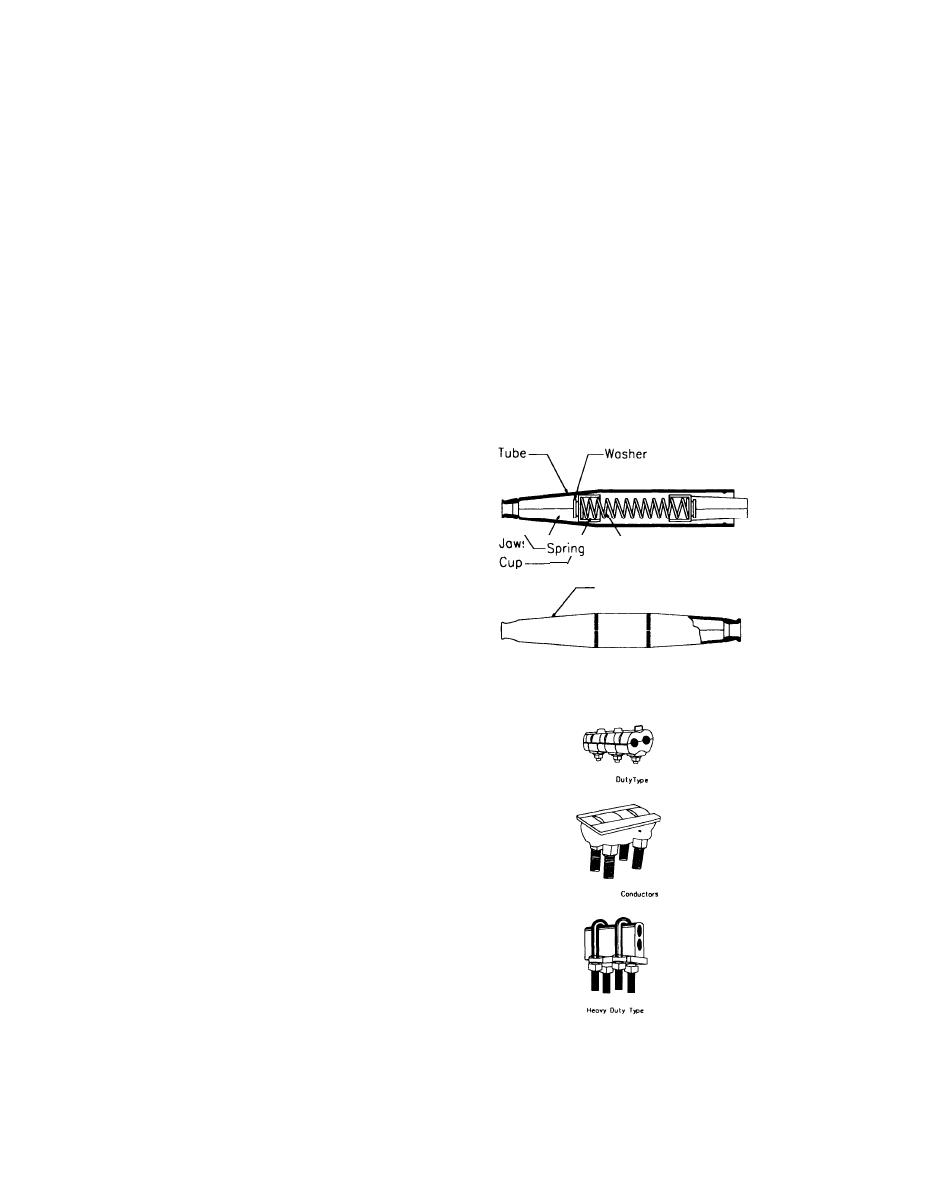

b. Automatic tension splice. Automatic tension or

The connection must be able to transmit the re-

line splices with their single-bore sleeve as shown in

quired load current and have sufficient mechanical

figure 4-14 can only be used in any span where the

strength to support the connection and the con-

wires are continually in tension. To install, force the

nected conductors. In general, the connection

gripping teeth of the splice jaws onto the conductor

should be suitable for installation without having to

by imposing several severe jerks on the conductor or

be joined to the main tension line conductor. Con-

by pulling on the conductors to obtain a tension

nectors are available in a wide range of sizes for

exceeding 15 percent of the rated breaking strength

connecting copper to copper, aluminum to alumi-

of the conductor. If an attempt is made to withdraw

num, and copper to aluminum. It is essential that

the conductor, the splice jaws will clamp down on

the proper size and type of connector be used. For

the conductor because of a taper in the bore of the

tapping conductors over No. 2/O AWG in size, a

sleeve and on the jaws. The tension causes a wedg-

stirrup should be used on each conductor, with a hot

ing action which increases with the pull applied on

line clamp, to avoid "burndown" of the feederline in

the conductor. A loss of tension could cause the jaws

to release their grip and allow the conductor to drop

the event of a heavy fault or "heated up" tap connec-

out. This type of splice is used where service must

tor.

be restored quickly and is especially suited for live-

line splicing.

(1) Care. Automatic line splices must be clean,

as any contaminants will impair the proper opera-

tion of the internal jaws. Splices that have lost their

original protective wrapping should be carefully in-

spected for any dirt. During installation and until

the conductor reaches its final installed tension,

automatic line splices should not be dragged

Cartridge Assembly

through any element that could cause soiling. Any

splice with a deformed or dented barrel will inter-

fere with the proper seating of the internal jaws and

should not be used.

(2) Unsuitable Locations. Splices should not be

Figure 4-14. Automatic tension splice

installed within 12 inches (300 millimeters) of a tie

wire or armor rod. Splices cannot be used in taps

and jumpers which have no tension, on conductors

of dissimilar metals, or where there is severe vibra-

tion.

c. Clamp splices. Bolted-type connectors as

Normal

shown in figure 4-15 are not recommended for

wires under tension. Most clamps are designed

primarily for conductivity and may not provide

the required strength unless two or more are

used.

d. Wires of different sizes. When the conductor

For Flexible

size changes at a pole, special construction is usu-

ally necessary for conductor attachment. Some au-

tomatic line splices are available for use where this

size difference is not great; but pins, insulators, and

the line ties must be strong enough to hold the

difference in tension between the two conductors.

Under the worst loading conditions, when this ten-

sion difference exceeds 500 pounds (225 kilograms),

automatic line splices are not recommended.

Figure 4-15. Clamp connectors (Courtesy of BURNDY Electrical)

4-20

|

|

|

|

||