Custom Search

|

|

|

||

TM 5-684/NAVFAC MO-2OO/AFJMAN 32-1082

a. Split-bolt connectors. Split-bolt connectors

(1) Burning of the main conductor at the con-

(bugs) are used extensively on lower voltage cir-

tact due to looseness and high resistance;

cuits, utilizing No. 2 AWG or smaller copper conduc-

(2) Difficulty of removal due to freezing of the

tors, and are also available in larger sizes. Where

bolt in the body. The clamp should be located where

vibration or twisting occurs, the contact pressure of

vibration and flexing of the tap wire will be a mini-

a split-bolt connector will relax and may cause arc-

mum. To prevent burning from damaging and pos-

ing, resulting in a burned-down conductor. Spacing

sibly dropping the main conductor, a hot line clamp

two connectors about 6 inches (150 millimeters)

should not be attached directly to the main conduc-

apart will reduce this hazard. Never reuse a split-

tor except in a nontension loop. The best method is

to attach a suitable stirrup, either clamp or com-

bolt connector, as it has probably been damaged in

removal. Any bending or forming of the conductors

pression type, and apply the hot line clamp to the

should be made before final tightening of the con-

stirrup. In this way, any burning at contact or arc-

nector. Never use split-bolt or similar type of con-

ing during removal will burn the stirrup and not

nectors for medium-voltage splices under tension.

damage the main conductor. Hot line clamps can be

b. Bolted connectors. Bolted connectors are of

applied over armor, if the contact between conduc-

tor and armor is thoroughly cleaned first. The prob-

various sizes and types, using one or more straight

lem of freezing threads is a matter of design, and

or U bolts to provide the contact pressure. The con-

ductors may make contact with each other or they

the more modern hot line clamps are much less

may be separated by spacers on the body of the

likely to have this trouble. Any hot line clamp that

clamp. Any bending or forming of the conductors

is not in good condition should be discarded.

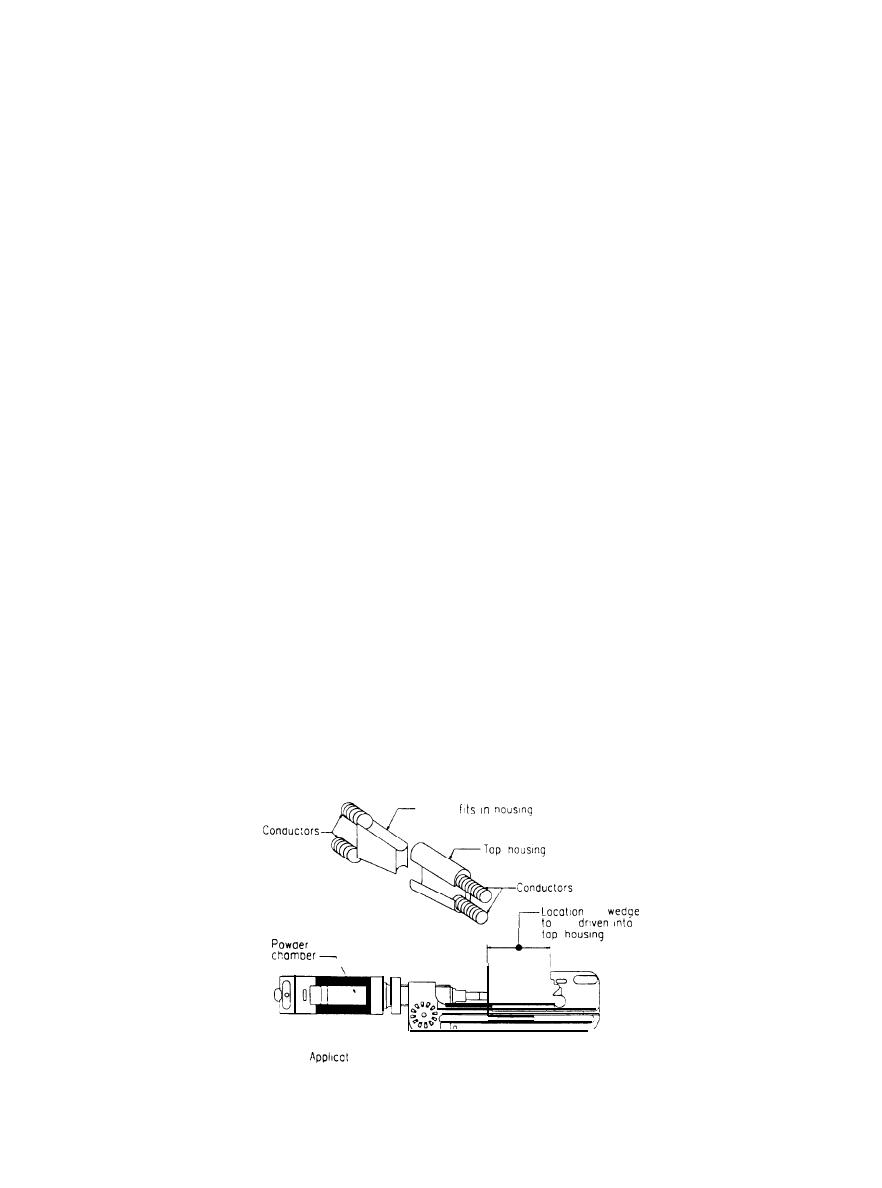

e. Internally-fired taps. Internally-fired taps are

should be completed before the final tightening of

the connector.

used for a tee connection on transmission and dis-

c. Compression tap connectors. Compression-type

tribution conductors of both copper and aluminum.

tap connectors are available in such forms as T, L,

The tap housing is made of a suitable alloy, tapered

and parallel. To fit over the main conductor without

at the ends where the conductors enter. The appli-

having to cut it, the connector has a U-shaped open-

cation tool as shown in figure 4-16 contains a high-

ing. This connection is not as strong as the full

strength steel powder chamber that is loaded with a

round splice connection, but if properly applied it is

fast-burning propellant charge contained in a poly-

superior to any bolted connection. The connector is

ethylene cartridge. A simple hammer blow deto-

nates the cartridge. Igniting the charge creates in-

not reusable, and removal requires cutting the main

stantaneous high pressure in the chamber. This

conductor. If the tap is no longer needed, the tap

wire may be cut off and the connector left on the

pressure drives cylindrical sets of wedge-shaped

serrated aluminum jaws (into which the conductor

main conductor.

d. Hot line clamps. Hot line clamps are used for

ends have been inserted) at high velocity into the

tapered ends of the housing. The jaws clamp and

either temporary or permanent connections in

lock the conductor ends in position, providing the

places where it is necessary or convenient to use hot

required holding strength and establishing a low-

sticks, and where the connection must be occasion-

ally opened. Hot line clamps are prone to two types

resistant current path across the housing. If cor-

of trouble:

rectly operated, a locking tab will verify the wedge

Wedge

of

be

\

on

tool-

Figure 4-l 6. Internally-fired tap components

4-21

|

|

|

|

||