Custom Search

|

|

|

||

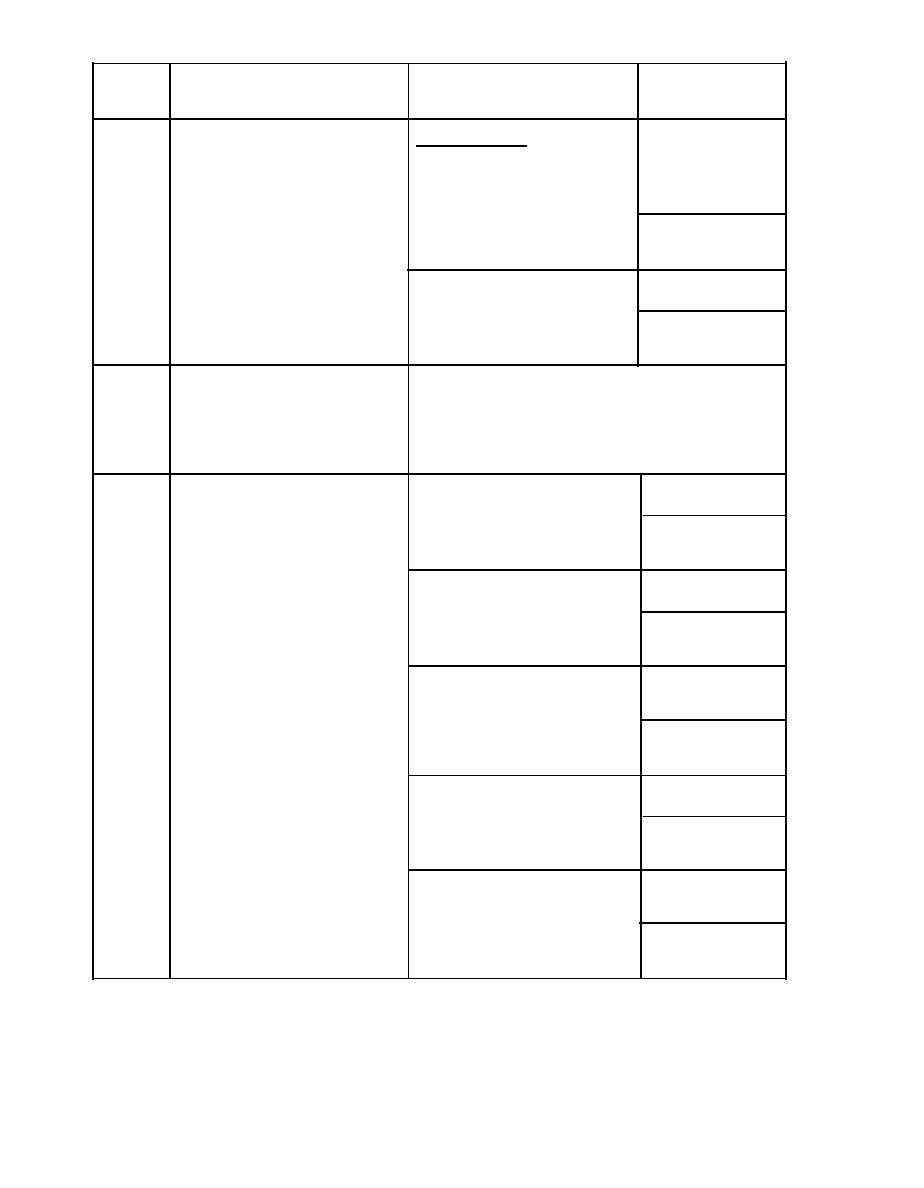

Troubleshooting Steam Traps (Continued)

TABLE 3-2.

Possible Cause/

Problem Indication

Normal Operation

Type Trap

Action

Sound Inspection

lost and

Continuous discharge on normal

F&T

Ioads. May be intermittent on

Noisy; high pitch sound.

Steam flowing

l i g h t load.

through; failed

open.

Replace or overhaul

trap.

No sound.

Failed closed.

Constant low pitch sound of

continuous flow.

Replace or overhaul

trap.

Thermo-

Discharge continuous or inter-

Same as for float trap above.

static

mittent depending on load,

pressure, type.

Constant low pitch sound of

continuous or modulating flow,

Inverted

Cycling sound of bucket opening

Steam blowing through.

Failed open.

bucket

and closing.

Quiet steady bubbling on light

Replace or overhaul

load.

trap.

No sound.

Failed closed.

Replace or overhaul

trap.

Discharging steadily; no bucket

Handling air; check

sound.

again in 1 hour.

Clear vent or re-

place trap.

Discharging steadily; bucket

Lost prime.

dancing.

Add prima or re-

place trap.

Discharging steadily; bucket

Failure of internal

dancing after priming.

parts.

Replace or overhaul

trap.

3-40

|

|

|

|

||