Custom Search

|

|

|

||

( f ) I n s t a l l a t i o n . Shutdown of the steam system at installation, and

e a c h time the orifice plate is checked or replaced, is necessary. An upstream

s t r a i g h t pipe run of 10 to 30 diameters is required.

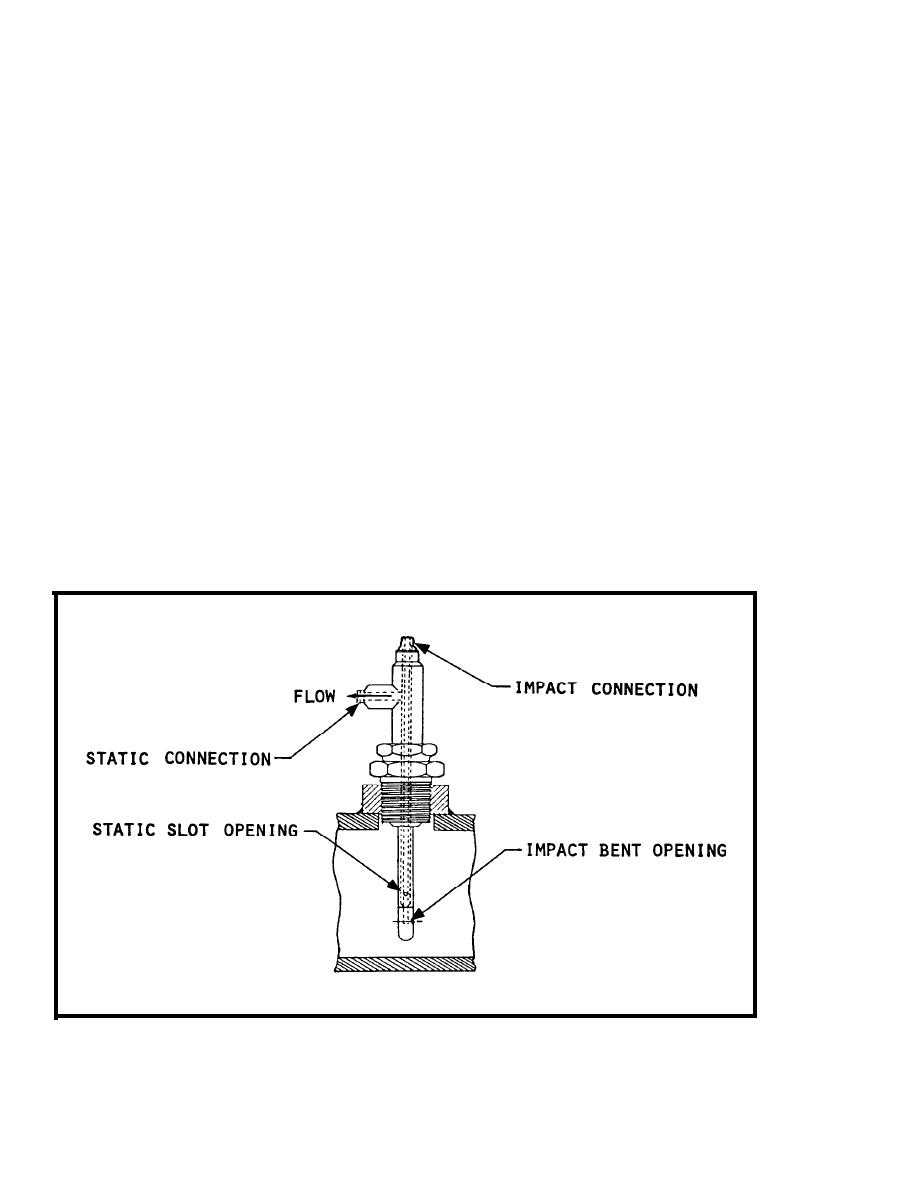

3 . 2 . 2 P i t o t T u b e s . T h e pitot tube, which is limited to single point

measurements, is another type of DP meter. Pitot tubes sense two pressures at

the same time, i m p a c t and static. An impact tube is open ended and has a 90

b e n d at the bottom; a static tube is straight, closed at the bottom, with a

s l o t in the side. The tubes may be mounted separately or combined coaxially

as shown in figure 3-15. Pressure taps are connected to a manometer where the

p r e s s u r e d i f f e r e n t i a l i s i n d i c a t e d . I t is common installation practice to

w e l d a coupling to a pipe and insert the probe through the coupling.

Pi tot

tubes have a minimum pressure drop and are low in cost, free of moving parts,

a n d easy to install, but are susceptible to being plugged by suspended matter

in the fluid.

3 . 2 . 3 Insertion Turbine Meters.

F i x e d and insertion turbine meters (figures

3 - 1 1 and 3-12) measure velocity of steam in a pipe with a rotor inserted at

t h e c r i t i c a l p o i n t i n t h e f l o w p r o f i l e . T h e critical point represents the

a v e r a g e flow velocity. T h e following items are characteristics of insertion

t u r b i n e meters.

( a ) Accuracy. A c c u r a c y within the turndown ratio of 25:1 is typically

%1 percent. T h e t u r n d o w n r a t i o i s s i g n i f i c a n t l y b e t t e r t h a n d i f f e r e n t i a l

pressure meters.

( b ) S i z i n g . Sizing is less critical than differential pressure meters

b e c a u s e of wide rotor range and ease of installation.

FIGURE 3-15.

Pitot Tubes Mounted in a Single Casing

3-48

|

|

|

|

||