Custom Search

|

|

|

||

(c) Check operation of the automatic drain traps. When the air pressure

is too low for proper operation of the traps, open manual drain valves for

direct drainage of condensate.

(d) Relieve air pressure in secondary air receivers by opening manual

d r a i n valves. This will also permit draining moisture condensate and sediment

accumulated in the tanks.

(e) In underground systems, keep draining equipment in service to remove

any water that may infiltrate into the manholes.

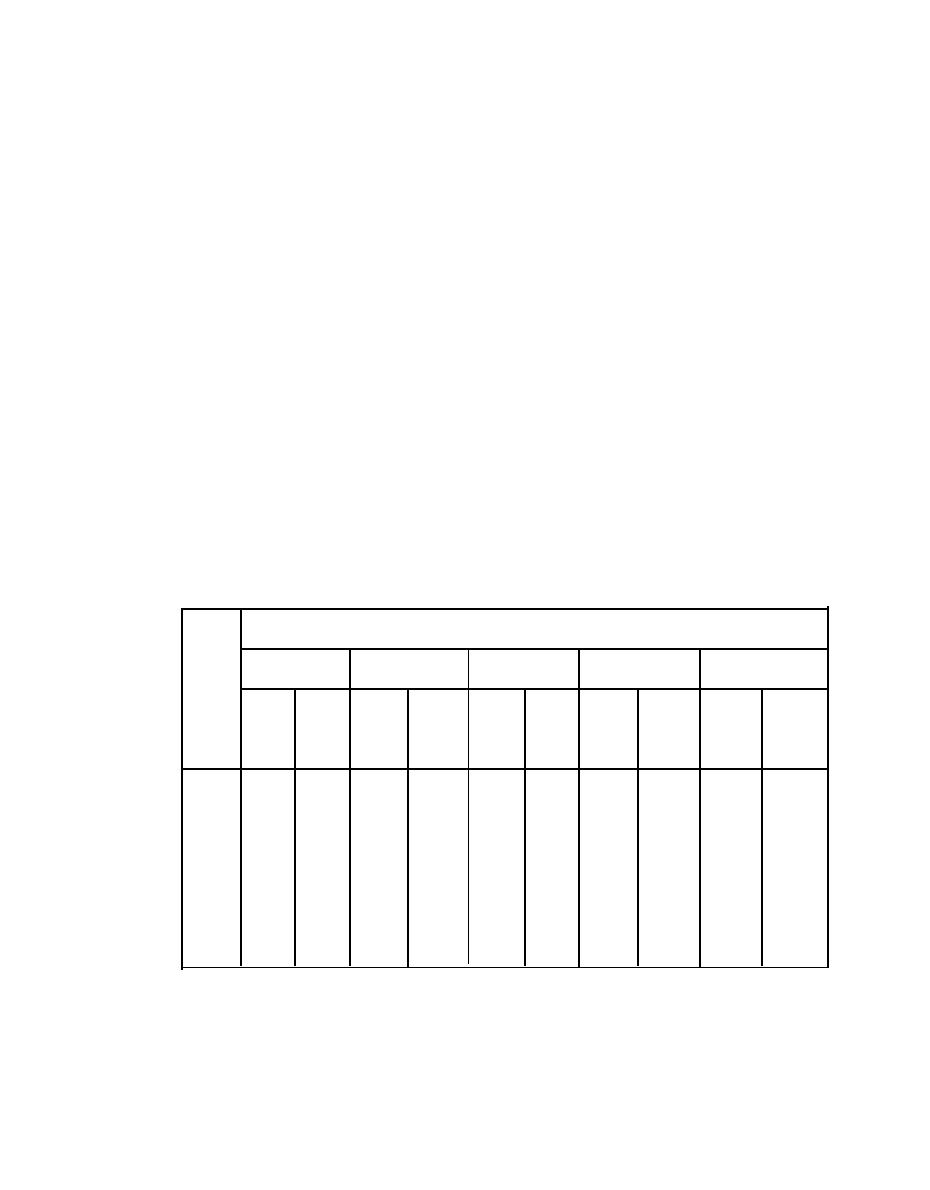

6 EMERGENCY PROCEDURES. R e p a i r all piping leaks as soon as possible. Refer

to table 5-2 for a quick estimate of the amount and cost of air leaks. The

d e f e c t i v e line can be isolated for repairs by closing segregating valves.

Often the service can be maintained to affected customers through an alternate

route by means of a loop closure.

7 CASUALTY PLANNING. M a k e certain operators are familiar with location and

arrangement of piping systems, v a l v e s , associated equipment, and controls. A

map of the area served, showing the location of the distribution piping,

equipment, and consumers, is very useful and should be available to

o p e r a t o r s . Give operators definite instructions on emergency procedures.

S c h e d u l e periodic practice fire drills, inspections, and other emergency

procedure tests. T r a i n all opertors in the use of available fire fighting and

emergency draining equipment.

Amount and Cost of Air Leaks1

TABLE 5-2.

Size of Hole (inches)

1/4

1/8

1/16

1 /32

1 /64

Cost

Air

Cost

Cost

Air

Cost

Air

Air

Air

Cost

Air

Per

Per

Losses

P e r Losses

Press.

Losses

Per

Losses

Per

Losses

(psig)

(cfm)

Month

(cfm)

Month

(cfm)

Month

(cfm)

Month

(cfm)

Month

$

$

$

$

$

815.00

9.42 203.50

37.8

50

0.146

3.15

0.594

12.80

2.37

51.00

60 0.169 3.65 0.682

14.75

2.73 59.00 10.9 235.50 43.5 940.00

70

0.192

4.15

0.773

16.70

3.09

65.50

12.3

265.50

49.4

1,065.00

80

0.214

4.60

0.864

18.65

3.46

74.50

13.8

298.00

55.2

1,190.00

90

0.237

5.10

0.955

20.60

3.81

82.00

15.3

330.50

61.1

1,330.00

100

0.260

5.60

1.05

22.70

4.19

90.50

16.8

363.00

66.9

1,445.00

110

0.279

6.00

1.14

24.60

4.55

98.00

18.2

393.00

72.8

1,570.00

120

0.305

6.60

1.23

26.55

4.93

106.50

19.6

423.50

78.6

1,695.00

130

0.325

7.00

1.33

28.70

5.28

114.00

21.1

455.50

84.5

1,825.00

140

0.351

7.60

1.41

30.45

5.64

122.00

22.4

484.00

89.7

1,935.00

150

0.370

8.00

1.51

32.60

5.98

129.00

23.8

515.00

95.5

2,060.00

0.429

9.25

1.72

37.15

6.89

149.00

27.4

590.00

110.0

2,375.00

175

0.494

10.65

2.00

43.20

7.93

171.00

31.6

680.00

127.0

2,745.00

200

Costs assume a continuously pressurized system.

1Airflow is based on nozzle coefficient of 0.64.

5-15

|

|

|

|

||