Custom Search

|

|

|

||

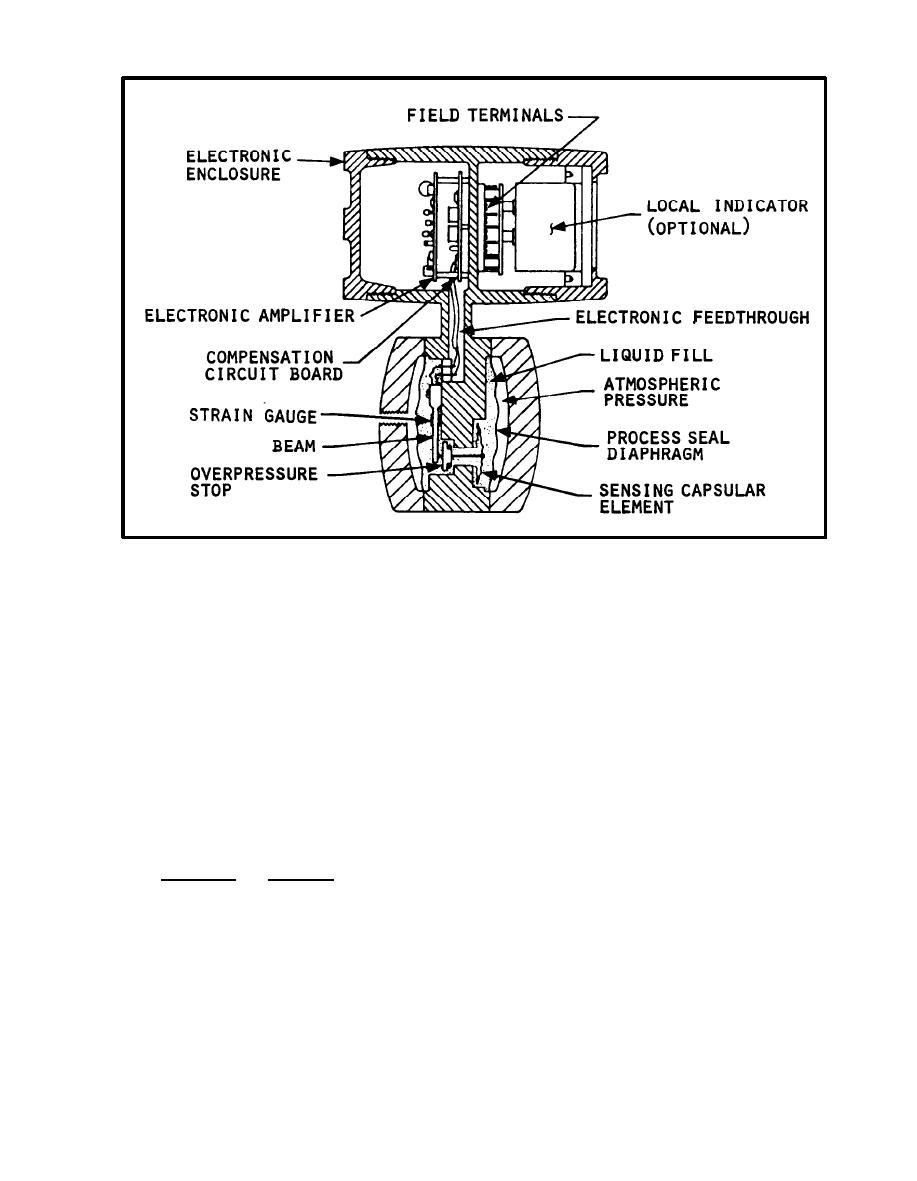

FIGURE 6-10.

S e c t i o n View of Electronic Pressure Transmitter

t h i s closes the valve until the spring force balances the thrust exerted

through the valve stem by the diaphragm. T h e reverse is true for a decrease

i n t h e f l u i d c o n t r o l l e d p r e s s u r e . The controlled pressure can be adjusted by

changing the spring compression. When this type of valve is used for remote

c o n t r o l , s i g n a l air pressure from a pneumatic transmitter is applied in the

top chamber over the diaphragm.

6 . 1 . 2 Valve Seating Arrangements. V a l v e s can be of the single-seated type or

o f the balanced type. S i n g l e - s e a t e d valves are used for dead-end service,

where a pressure must be maintained during no-flow periods. T h i s type of

v a l v e can be closed tightly. B a l a n c e d valves require smaller forces to

o p e r a t e since the pressure acts on both sides of the disk. They do not close

t i g h t l y . S o m e valves are V-ported to provide throttling in the early stages

o f opening and closing.

6.2 Temperature Controls. T h e s e controls are used to maintain a substantially

c o n s t a n t temperature in one part of the system, regardless of load

P e r m i s s i b l e variations must be within the range of the

fluctuations.

equipment.

6.2.1 Temperature Control Components. A temperature control has three basic

elements which include a temperature sensing device (temperature bulb); a

r e g u l a t i n g valve, generally actuated by a bellows, to control the passage of

t h e heating or cooling fluid; and necessary capillary tubing connecting the

t e m p e r a t u r e bulb with the bellows. T h e temperature bulb, capillary tubing,

a n d bellows system are filled or partly filled with liquid, gas, or a

6-15

|

|

|

|

||