Custom Search

|

|

|

||

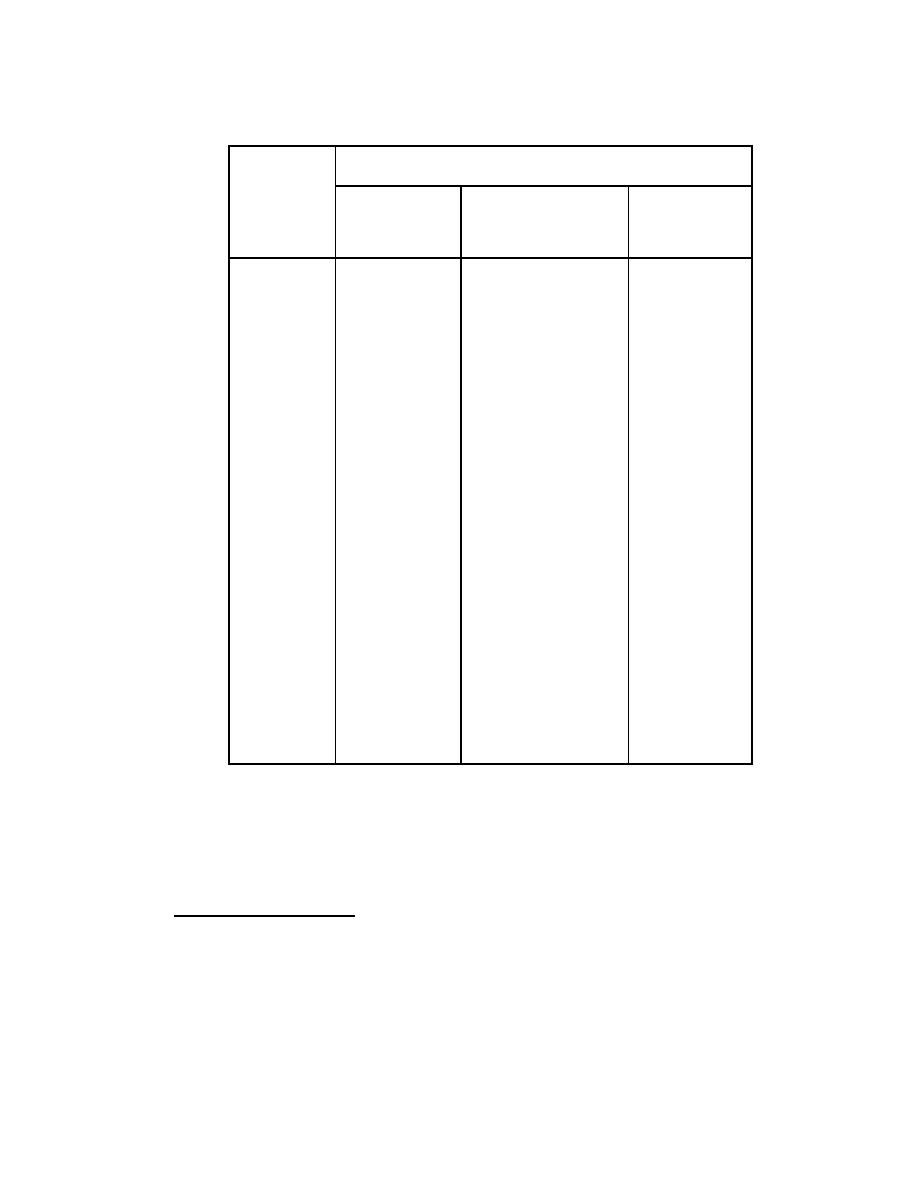

TABLE 7-3.

Pipe Expansion per 100 Feet of Length

With Temperature Changes

E x p a n s i o n in Inches for Different Materials

Tempera-

Copper

Wrought Iron

ture (F)

Steel

(4)

(1)

(2

)

(3)

o

0

0

0

0.238

0.148

0.180

20

0.451

40

0.300

0.350

0.540

0.684

60

0.448

0.710

0.896

80

0.580

1.134

0.753

0.887

100

1.058

1.366

120

0.910

1.240

1.590

140

1.064

1.420

1.804

160

1.200

1.360

1.580

2.051

180

1.520

1.750

2.296

200

1.940

2.516

220

1.680

2.756

1.840

2.120

240

2.300

2.985

260

2.020

2.470

3.218

280

2.180

3.461

300

2.350

2.670

3.696

320

2.530

2.850

3.040

3.941

340

2.700

4.176

2.880

3.230

360

4.424

3.425

380

3.060

4.666

400

3.230

3.620

3.820

4.914

420

3.421

440

3.595

4.020

5.154

3.784

4.200

5.408

460

4.400

5.651

480

3.955

4.151

5.906

4.600

500

1

E x p a n s i o n in inches per 100 feet length of pipe, from

0F to pipe temperature shown in column (l).

absorbing vibrations or mechanical movements to ambient temperatures may be

m a d e of copper or other materials suitable for the job conditions. A maximum

t r a v e l of 4 inches should be allowed for this type of joint.

3.3 Flexible Ball Joints.

B a l l joints consist of four main components:

( a ) The casing or body that holds the gaskets and ball

(b) The ball itself, which fits inside the casing

( c ) The inner and outer gaskets, i n s t a l l e d between the ball and the

c a s i n g , to provide a seal

7-7

|

|

|

|

||