Custom Search

|

|

|

||

MOISTURE SEPARATORS AND DRIP LEGS

Section 2.

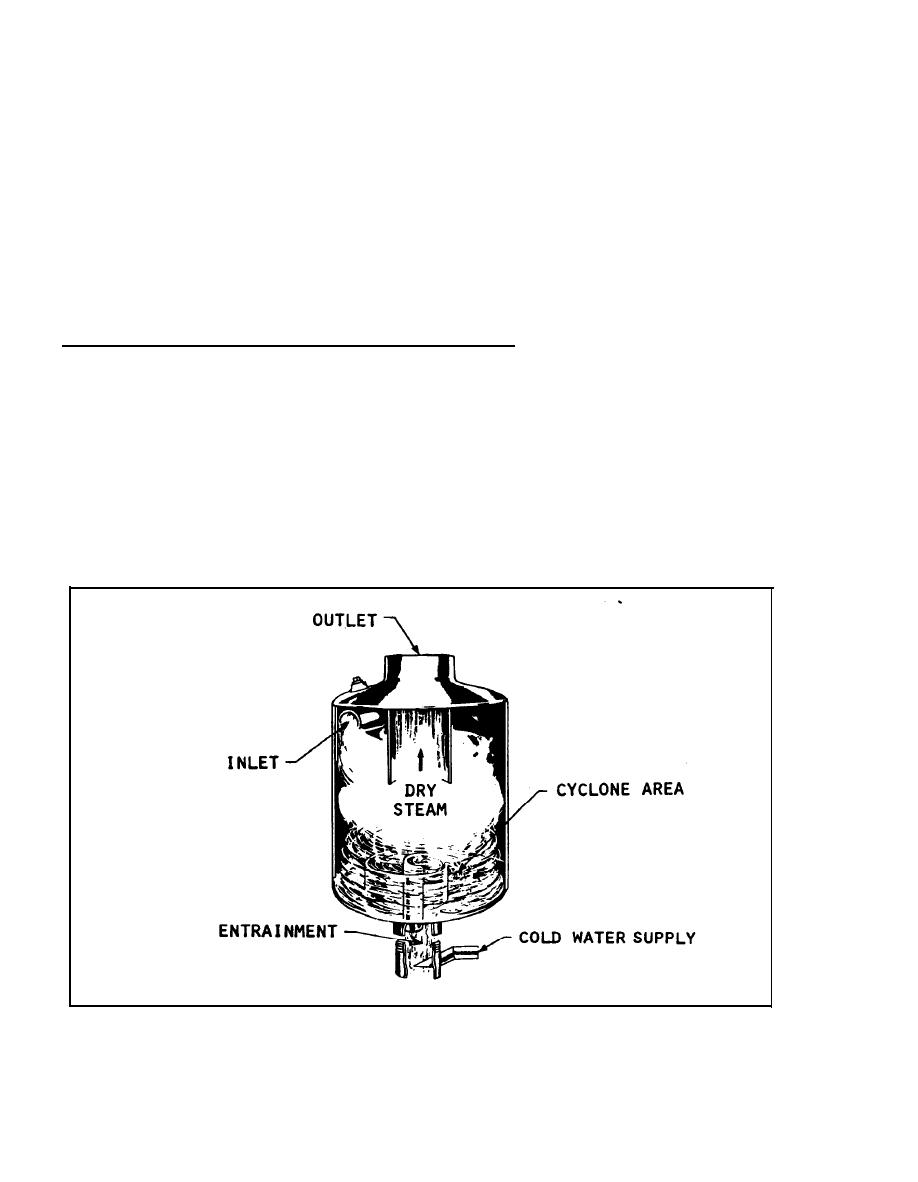

1 MOISTURE SEPARATORS. Various types of blowdown and inline separators are

u s e d in distribution lines to separate entrained water, oil, and particles

from steam, compressed air, or gases. ( R e f e r to figures 8-12, 8-13, and

8 - 1 4 . ) All moisture separators use the principles of a vortex and centrifugal

force to separate the moisture from steam or gas. As steam enters a

s e p a r a t o r , the design of the inlet or stationary baffle vanes cause the steam

t o swirl in a cyclone-like vortex against the the walls of the vessel. The

i n c r e a s i n g velocity of the vortex causes centrifugal force to deposit the

m o i s t u r e on the walls of the vessel. The moisture then drops to the bottom of

t h e separator and is eliminated through a trap or directly into a drain line.

Once entrainment has been eliminated, clean, dry steam flows through the

center of the vortex to an outlet and back into the flow line. NAVFAC MO-206,

Operation and Maintenance of Air Compressor Plants, addresses the usage and

m a i n t e n a n c e of moisture separators.

2 DRIP LEGS. D r i p legs are provided to collect condensate from steam lines

and compressed air lines. The condensate is generally removed by traps,

a l t h o u g h manual drain valves are often used for compressed air lines. Drip

l e g s are usually located at low points, a t the bottom of all risers, and at

i n t e r v a l s of not over 200 feet for horizontally pitched pipes where traps are

accessible.

I n buried underground pipe installations, where the traps are

i n a c c e s s i b l e , drip legs are usually located at intervals of not over 350 feet.

Moisture Separators - Downdraft

FIGURE 8-12.

8-18

|

|

|

|

||