Custom Search

|

|

|

||

CHAPTER 5.

DIFFERENTIAL PRESSURE METERS

Section 1.

ORIFICE PLATE METERS

1. INTRODUCTION. Orifice plate meters are the most common meter used in

industry today. It is estimated that over 50 percent of the devices used for

measuring fluids are orifice plate type. The widespread use of orifice plates

provides a great deal of background and operational experience in a variety of

situations.

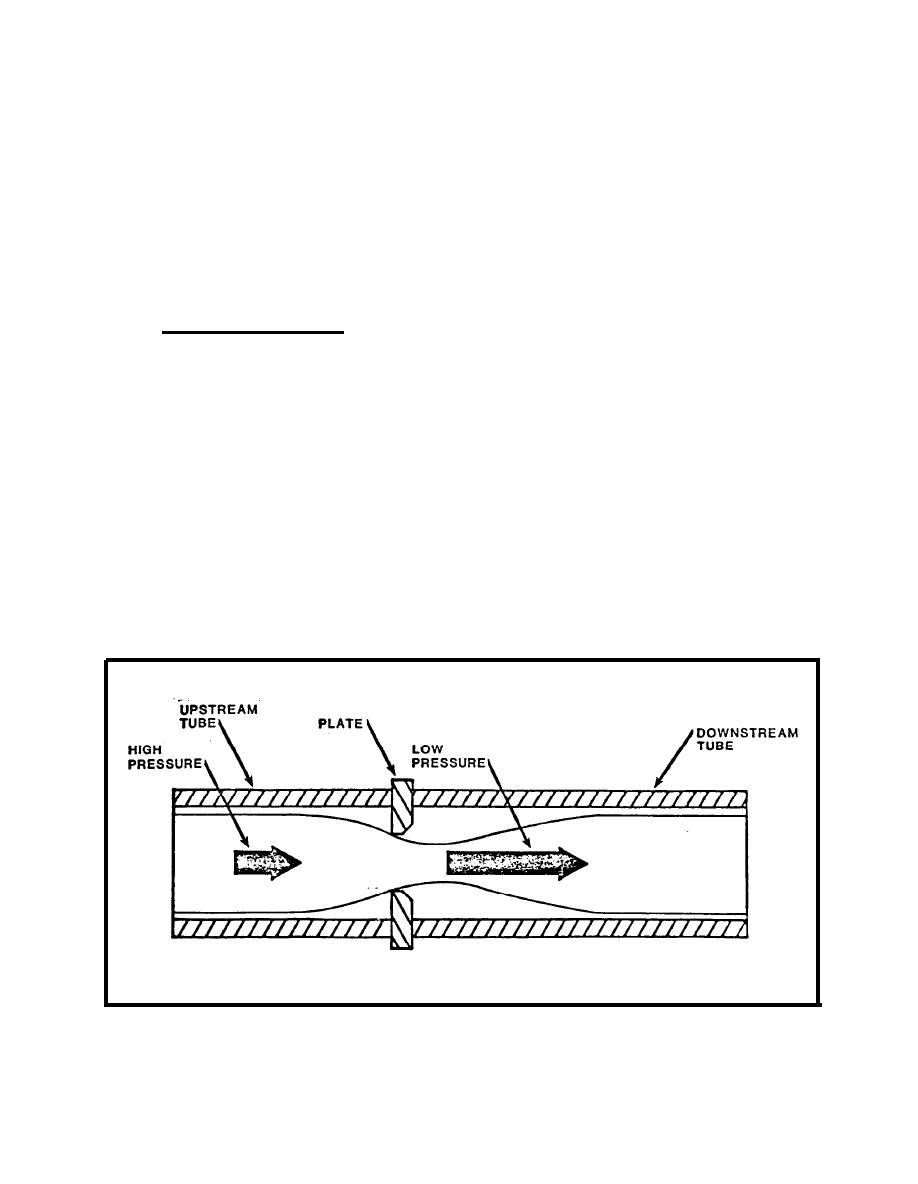

1.1 Operating Principles. Orifice plates can be used to measure flow because

of the velocity-pressure relationship that exists in a flowing fluid. When a

restriction, such as an orifice plate, is inserted into a stream, the fluid

velocity must increase when passing through the restriction. The increase in

velocity is accompanied by a proportional drop in pressure on the downstream

side of the orifice plate (Figure 5-l). Since the pressure drop across the

meter is proportional to the square of the flow rate, it is possible to

calculate the flow rate by measuring the differential pressure (alp) before and

after the orifice. Instruments of this type are known as inferential meters

as they do not physically measure the flow, but rather "infer's it from the

known relationship between pressure and velocity.

2. METER DESIGNS. There are different orifice plate designs such as

square-edged, one-quarter circle, and conical. For the q ajority of flow

measurements involving gases, air, steam, and water, the square-edged orifice

plate is used. Other configurations are primarily designed to address

particular situations such as high viscosity, erosive fluids, and fluids

containing suspended material.

FIGURE 5-1.

Typical Orifice Plate Conditions

5-1

|

|

|

|

||