Custom Search

|

|

|

||

Section 2.

VENTURI TUBES

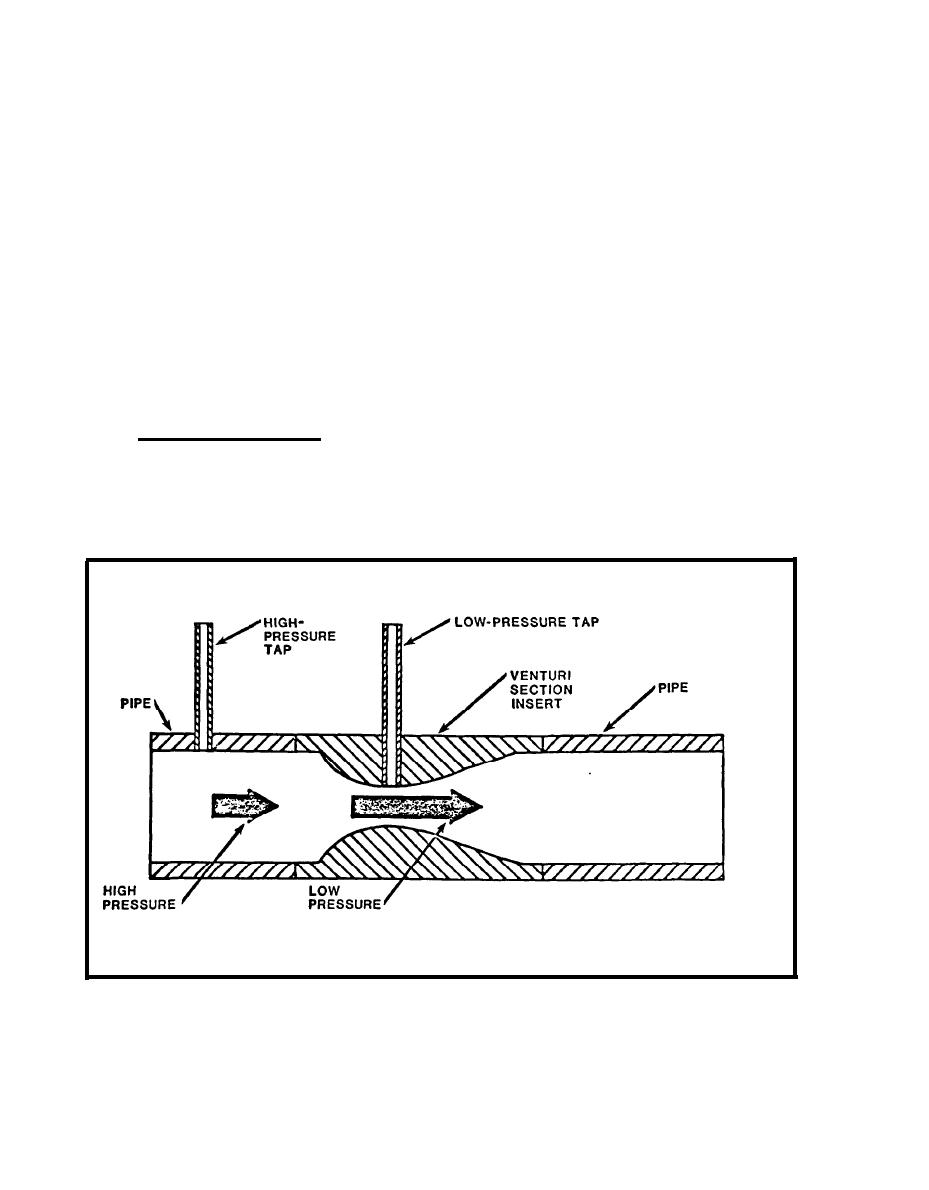

1. INTRODUCTION. Venturi tubes are used to measure flow in pipes and ducts.

They can be applied to gases such as air and steam, and to liquids such as

water and oil. Common applications include airflow in large ducts and steam

output from boilers. Venturis are widely used, and a great deal of operating

experience has been gained in a variety of applications. They are relatively

easy to fabricate, consisting of a tube that gently converges to a low

diameter throat and diverges to the downstream pipe diameter (Figure S-ll).

If the cost of fluid delivery is high, venturis are desirable because they

have a low, permanent pressure loss and do not decrease the delivery rate.

Venturis have a low sensitivity to wear and are useful in erosive flows such

as air with suspended solids. Venturi meters are especially applicable to

large ducts , round or rectangular, where other types of flowmeters are

expensive to fabricate and calibrate.

1.1 Operating Principles. Venturi tubes are inferential meters that do not

measure flow directly, but cause differential pressure to occur. An inferred

flow rate can be calculated by measuring change in pressure and by knowing

proportional relationships. Figure 5-11 illustrates in a cutaway view, the

venturi and the areas of high and low pressures associated with their

respective velocities.

FIGURE 5-11.

Venturi Tube

5-15

|

|

|

|

||