Custom Search

|

|

|

||

Section 4. ULTRASONIC FLOWMETERS

1. INTRODUCTION. Ultrasonic flowmeters employ a basic principle of frequency

shift (doppler effect) to measure flow rate of liquids. This type meter is

totally exterior to the pipe, creates no pressure drop, and is not worn or

damaged by liquids or slurries being measured. Being exterior, these

flowmeters are constant in cost regardless of pipe size.

1.1 Operating Principles. Ultrasonic flowmeters use transducers to send and

receive reflected signals from impurities in the flowing liquid measured. The

signals are unaffected by temperature, density, or viscosity of the fluid.

2. METER DESIGNS. Ultrasonic flowmeters are divided into two groups, doppler

effect and time-of-travel. Both designs provide accurate measurements for

flow in either direction.

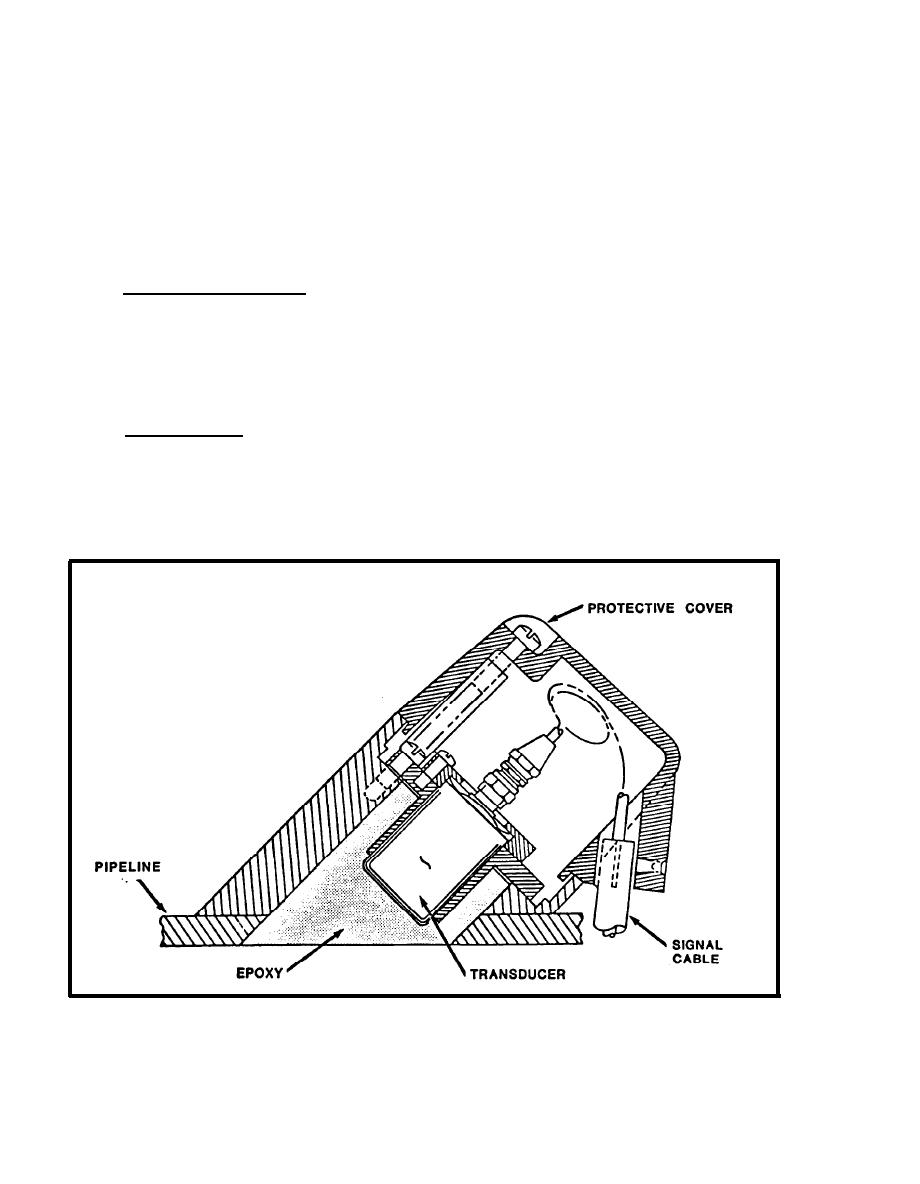

suspended particles in a flowing liquid. Two transducer elements are

contained in a single transducer, a transmitting element and a receiving

element. The transducer is potted in epoxy and inserted inside a fitting that

has been welded to the pipe (Figure 6-11). A window cut in the pipe allows

the transmitted signal of the transducer to enter the liquid, strike a

particle, and be reflected back to the transducer. Solids, bubbles, or other

FIGURE 6-11.

Doppler Ultrasonic Flowmeter

6-20

|

|

|

|

||