Custom Search

|

|

|

||

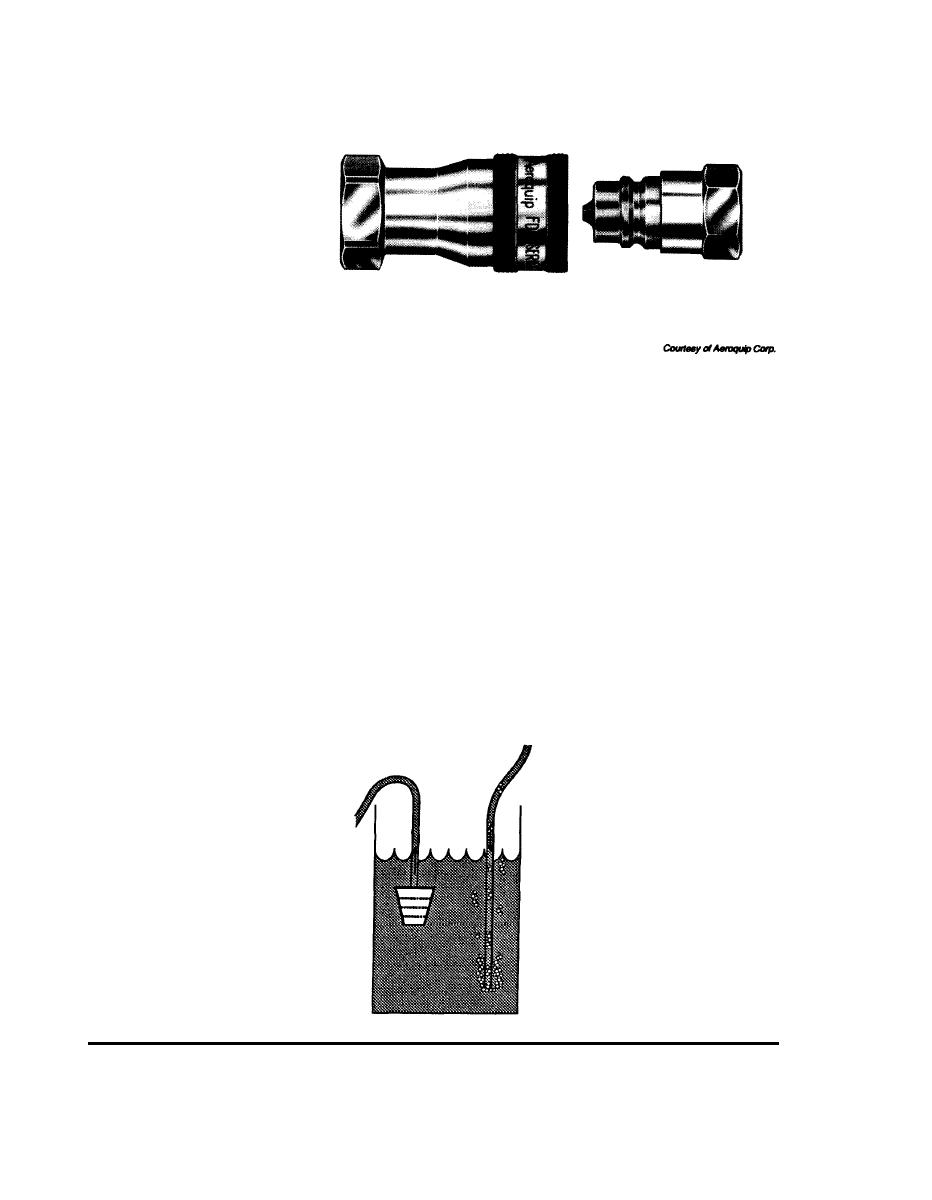

FIGURE 5-29

Special Fill/Drain

Assembly Fittings

The fluid in the bucket is pulled through the charging pump and into the system.

The check valve forces the fluid to move up the feed line to the collectors, up

through the collectors, back down the return line and back into the bucket (The

same way boiler/baseboard loops are initially filled).

If a gate ball valve is used instead of a check valve, it must be closed during the

charging process.

The drain port hose is submerged in the fluid to make it easy to see any air bubbles

coming out of the system. This is similar to the process of bleeding automobile

brakes.

Pour enough fluid into the bucket to fill it to within about two inches from the top of

the bucket. Make sure all vents are closed, and turn on the charging pump. Very

quickly, air will come out the drain hose (Figure 5-30).

FIGURE 5-30

Air Coming From the

Drain Hose

REPAIR

182

|

|

|

|

||