Custom Search

|

|

|

||

Lubrication

The motors of wet rotor pumps never require lubrication. External motor pumps

should be checked at every inspection. If there is no way to determine lubricant

levels, a regular schedule for adding oil should be established, to avoid over-oiling

the motor.

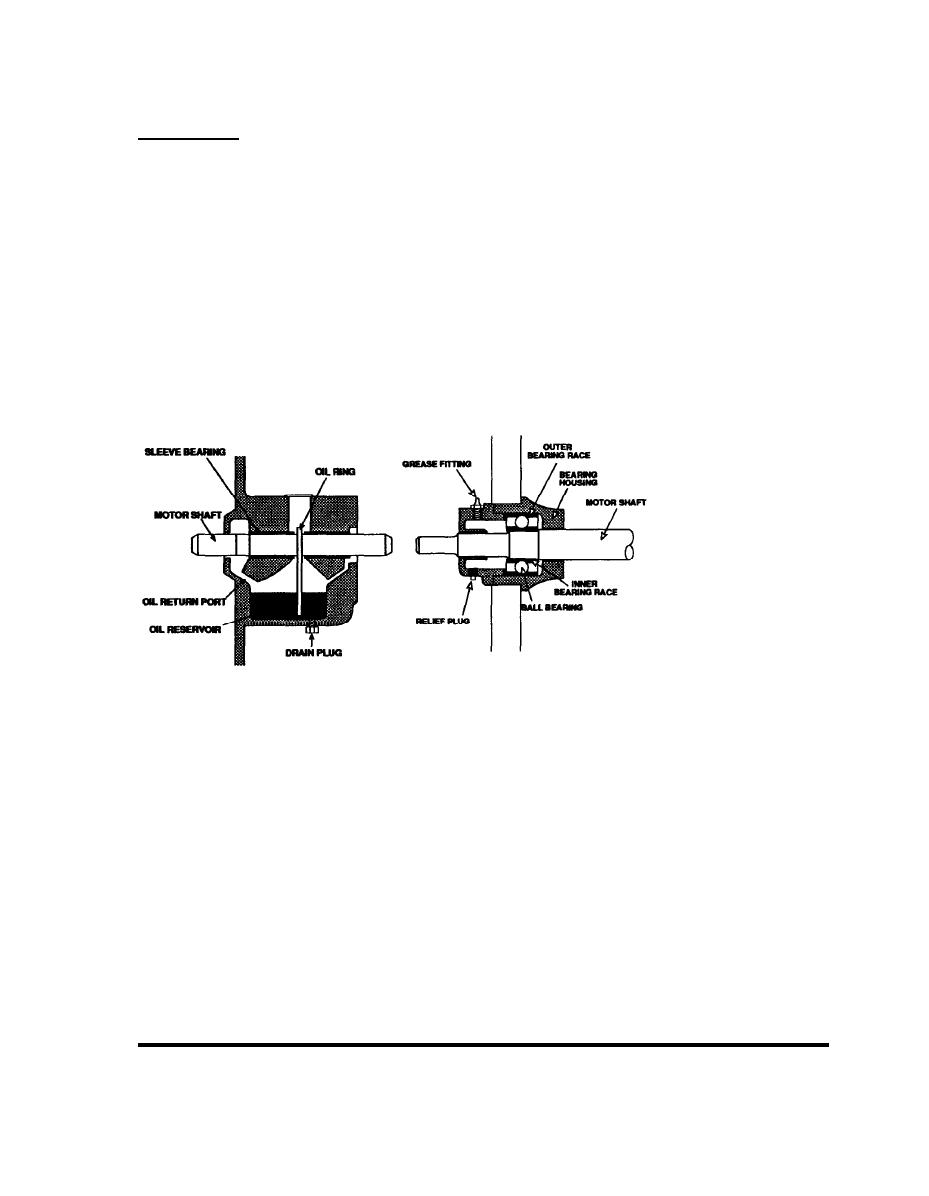

Add oil to sleeve bearings very slowly. When you see it coming from the overflow

hole, or the indicator cup is full, enough has been added (Figure 6-7).

Ball bearings are greased, rather than oiled (Figure 6-7). The entire assembly of

those that are permanently lubricated must be replaced when worn out.

FIGURE 6-7

Sleeve Bearings

Lubricated by Oil

(left)

and Ball Bearings

Lubricated by

Grease (right)

If grease can be added, remove the relief or drain plug, and add grease with a

grease gun on the fill ("zerk") fitting. Keep filling until all the old, dirty grease has

been pushed out the plug. The motor can be run during filling to make it easier, as

long as the pump is not assembled and being run without liquid.

Do not attempt to add grease without removing the relief plug. Leaving the plug in

will cause the bearings to be packed solidly. This may cause overheating and

bearing failure.

MAINTENANCE

6.1 MAINTENANCE PROCEDURES

213

|

|

|

|

||