Custom Search

|

|

|

||

MO-912

TM

flow of high-pressure oil to a servomotor, thereby

operating fuel controls.

(b) The isochronous system uses electronic

sensing and amplifying devices that actuate a type

of servomotor throttle control. The system is used

with power generation where precise frequency con-

trol is required. An isochronous system may be sen-

sitive to frequency changes (engine speed) or to both

frequency and load. When responsive to load

changes, the system corrects fuel settings before

load changes can appreciably modify engine speed

or frequency.

3-9. Air intake system.

Approximately 15 pounds of air is required to burn

one pound of fuel. Accordingly, the air requirement

for a 2000 horsepower engine is about 3600 cubic

feet per minute. The same horsepower-to-air rela-

tionship applies to engines for other power ratings.

Intake air carries dust particles, water vapor and

FROM ENGINE

other foreign material. Since these materials can

damage moving parts within the engine, filtration

of the intake air is necessary. A 2000 horsepower

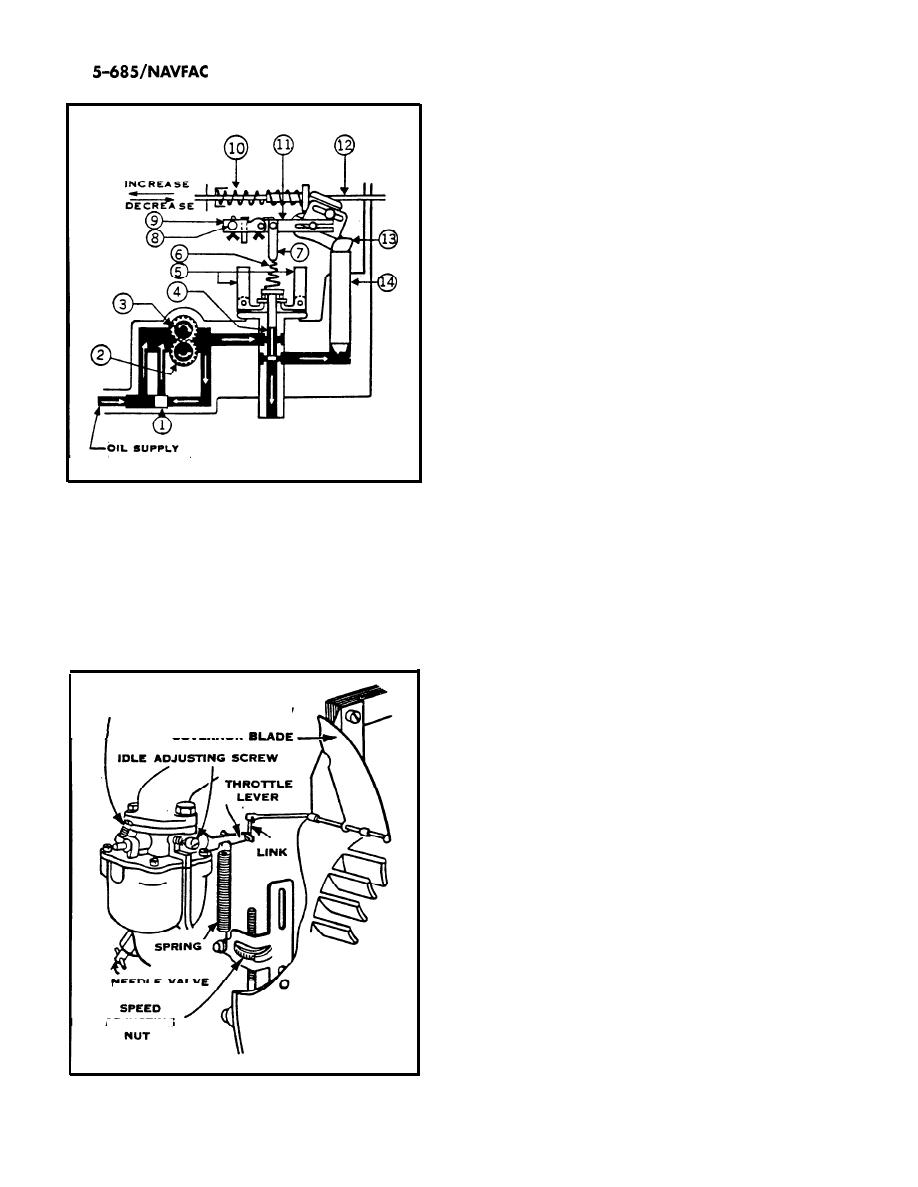

Figure 3-13. Hydraulic Governor.

1) PLUNGER, 2) GEAR PUMP DRIVE, 3) GEAR PUMP

engine, breathing air containing three parts per

IDLER, 4) PLUNGER PILOT VALVE, 5) FLYWEIGHT,

million dust contamination, would take in 25

6) SPEEDER SPRING, 7) SPRING FORK,

pounds of foreign material in 1000 operating hours.

8) SPEED-ADJUSTING SHAFT, 9) SPEED-ADJUSTING

An air intake system must collect, filter, and dis-

LEVER, 10) SPRING, 11) FLOATING LEVER,

tribute the required air to the engine cylinders. This

12) FUEL ROD, 13) TERMINAL LEVER,

14) SERVO PISTON

must be accomplished with a minimum expenditure

of energy (pressure drop). The objective of air filtra-

tion is the reduction of engine component wear. Sev-

eral types of air filters or air cleaners are used. The

pleated-paper type are strainers, porous enough to

pass air but able to remove solid particles larger

THROTTLE

ADJUSTING

SCREW

than 0.002 of an inch. Larger engines use an oil-

GOVERNOR

bath air cleaner (see fig 3-15). In oil-bath cleaners

air is drawn through an oil bath. Solid particles are

trapped and settle in the unit's bottom pan.

a. Supercharging. Supercharging increases the

amount of air taken into a working cylinder. This

provides the injected fuel oil with more oxygen to

enable combustion of a larger charge of air/fuel mix-

ture. Power output of a certain size engine is

thereby increased, enabling use of smaller engines

where space prohibits larger engines.

(1) Advantages. The power output of a natu-

rally aspirated engine is limited by the normal pres-

sure and oxygen content of the atmosphere. When

supercharging is used, the intake valve (port) closes

NEEDLE VALV

with the cylinder under the initial pressure. Super-

charging is particularly effective at higher alti-

ADJUSTING

tudes. The supercharged engine can develop greater

horsepower than the standard naturally-aspirated

unit. The fuel consumption of a supercharged unit

will not exceed that of comparable horsepower sizes

of naturally-aspirated units.

Figure 3-14. Carburetor and pneumatic governor.

3-20

|

|

|

|

||