Custom Search

|

|

|

||

TM 5-685/NAVFAC MO-912

but the coolant should be allowed to circulate

through the supercharger.

(4) Operating instructions. Manufacturer's in-

structions must be followed to ensure proper opera-

tion of superchargers. Filtered air only should enter

the air inlet, because foreign matter can cause rotor

imbalance and damaging vibration. The manufac-

turer's recommendations for lubrication must be fol-

lowed. Proper lubrication is necessary because the

unit operates at high speed and at high tempera-

ture. Not more than 15 seconds should elapse be-

tween the start of rotation and an oil pressure indi-

cation of 12 to 71 psi. Coolant circulation through

the turbocharger should be regulated so the tem-

perature rise does not exceed 30" Fahrenheit at full

engine load. A rise in excess of 30" Fahrenheit indi-

cates faulty circulation. Coolant should be allowed

to circulate through the turbocharger for about 5

minutes after the engine is shutdown.

b. Aspiration. The term "naturally-aspirated" is

applied to engines that are not supercharged. A four

stroke cycle engine performs its own air pumping

action with the piston intake stroke. When it is

supercharged, a four-stroke engine with a blower or

turbocharger provides pressure in the intake mani-

fold greater than atmospheric. The increased pres-

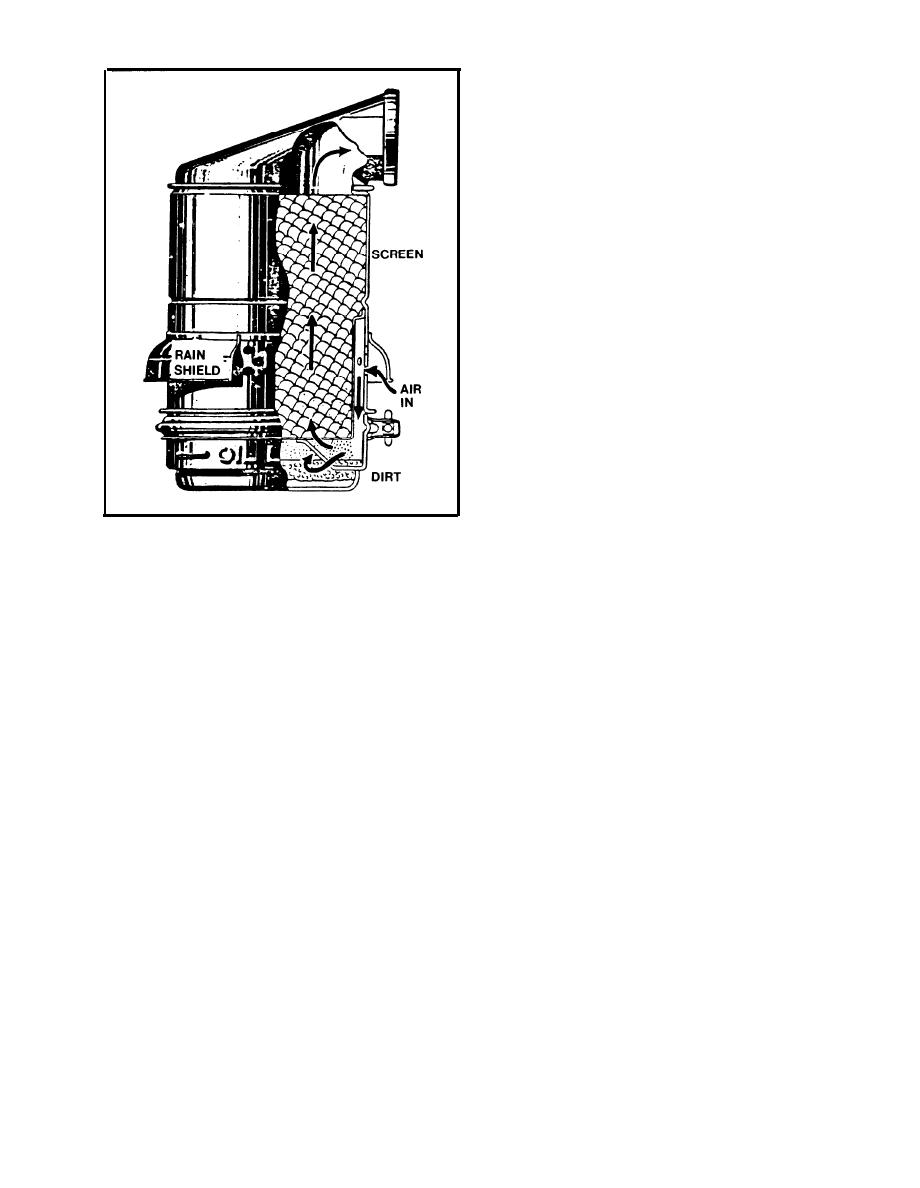

Figure 3-15. Oil bath air cleaner:

sure in the intake manifold is referred to as "boost".

Two stroke cycle engines require an air supply un-

(2) Methods. The most successful method of su-

der pressure to provide scavenging air.

percharging is the use of a turbocharger driven by

3-10. Exhaust system.

exhaust gas (see fig 3-16). The heat and energy

pulsations in the exhaust gas, which are usually

Components. The exhaust system consists of the

lost in the exhaust silencer, are used to drive a

engine exhaust manifold and includes piping, ex-

single-stage centrifugal turbine. The exhaust gas

pansion joints, silencers, and exhaust pipe. Also the

turbine is coupled to a centrifugal compressor that

system may include exhaust waste heat recovery

compresses the air to a pressure of four or five

equipment. The purpose of the system is to remove

psi. The engine's pressurized air is then delivered to

exhaust gas from engine cylinders to the atmo-

the individual cylinders through the intake mani-

sphere. Parts of the system are shown in figure 3-6.

fold.

(3) Disadvantages. Although the supercharged

to protect personnel from asphyxiation, and equip-

engine has many advantages over nonsupercharged

ment from fire and explosion. Exhaust from gaso-

line engines can contain dangerous carbon monox-

engines, its disadvantages are not insignificant. The

ide. Diesel engine exhaust includes objectionable

turbocharger is another piece of equipment to main-

smoke and odors. On supercharged engines, leaks

tain and operate. It operates at varying speeds de-

ahead of the turbine cause a loss of power.

pending on engine load, barometric pressure, inlet

(b) Piping. Exhaust piping must be the correct

air temperature, exhaust temperature, smoke con-

size to minimize exhaust back pressure. Connec-

tent of the exhaust, or accumulations of dust and

tions between exhaust manifold and piping should

dirt on the impeller and diffuser. It may operate at

have an expansion joint and the exhaust pipes

very high speed (up to 120,000 rpm) with a full load

should slope away from the engine. Also the exhaust

on the engine and thus be subjected to all the

pipes should have suitable devices to prevent entry

troubles of high-speed equipment. With proper

of rainwater. The length of tail pipes from silencer

maintenance, however, the turbocharger can be op-

to atmosphere should be kept to a minimum.

erated very successfully. If the turbocharger fails,

(c) Silencers. Silencers are used to reduce or

the engine can usually be operated at reduced load

muffle engine exhaust noise. Silencing engine ex-

as a nonsupercharged engine. The turbocharger can

haust sounds consists of trapping and breaking up

be partially dissembled and the opening blocked off,

3-21

|

|

|

|

||