Custom Search

|

|

|

||

TM 5-685/NAVFAC MO-912

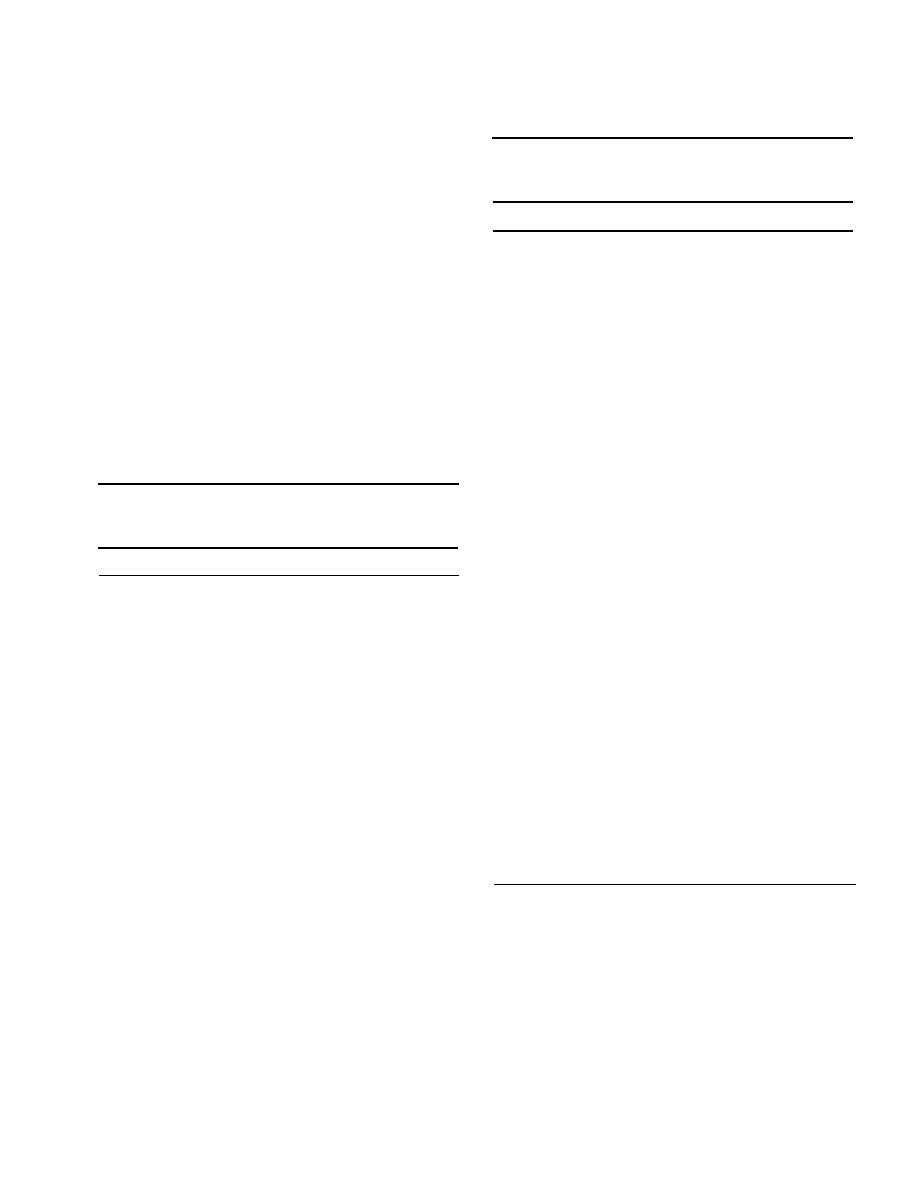

Table 5-l. Low voltage circuit breaker

the pin in place, the contacts will close slowly when

troubleshooting-Continued

the breaker is manually operated. Inspect connec-

tions for signs of arcing or overheating. Replace

Note

faulty connectors and tighten all connections. Clean

Refer to manufacturer's l i t e r a t u r e for specific information on

the connecting surfaces. An infrared (IR) survey is a

individual circuit breakers.

recommended inspection procedure. The IR survey

should be performed when the circuit breaker is

Cause

Remedy

under load and closed to detect overheating of con-

FALSE TRIPPING

nections. Perform general troubleshooting of the

Check application of overcurrent

Overcurrent pick-up too low

breaker (refer to the following table) if a problem

trip device

develops. If the trouble cannot be corrected, refer to

Check application of overcurrent

Overcurrent time setting too short

the manufacturer's literature for specific informa-

trip device

tion on individual breakers. Instrument transform-

Mechanical binding in over-

Correct binding or replace over-

ers require no care other than keeping them dry

current trip device

condition current trip device

and clean. Refer to manufacturer's literature if spe-

cific information is required. Information related to

Captive thumbscrew on power sen- Adjust power sensor. Tighten

sor loose. Fail safe circuitry reverts thumbscrew on desired setting

control circuit components is provided in paragraph

characteristics to minimum setting

5-3e of this chapter.

and maximum time delay

Ground sensor coil improperly con- Check polarity of connections to

coil. Check continuity of shield

nec ted

Table 5-l. Low voltage circuit breaker troubleshooting.

and conductors connecting the ex-

ternal ground sensor coil

Note

FAILURE TO CLOSE AND LATCH

Refer to manufacturer's l i t e r a t u r e for specific information on

Binding in attachments preventing Realign and adjust attachments

individual circuit breakers.

resetting of latch

Remedy

Cause

Latch out of adjustment

Adjust latch

OVERHEATING

Replace spring

Latch return spring too weak or

Adjust contacts

Contacts not aligned

broken

Clean contacts

Contacts dirty, greasy, or coated

Hardened or gummy lubricant

Clean bearing and latch surfaces

with dark film

Safety pin left in push rod

Remove safety pin

Replace contacts

Contacts badly burned or pitted

Replace motor

Motor burned out

Clean surfaces of current-carrying

Current-carrying surfaces dirty

Replace or adjust faulty device

Faulty control circuit component

parts

BURNED MAIN CONTACTS

Corrosive atmosphere

Relocate or provide adequate en-

Increase arcing contact wipe Adjust

Improper contact sequence (main

closure

contact opening sequence Refer to

contacts not sufficiently parted

Increase capacity of bus or cable

Insufficient bus or cable capacity

when arcing contacts part)

opening. Refer to manufacturer's

literature for contact maintenance

Tighten, but do not exceed, elastic

Bolts and nuts at terminal connec-

and adjustment information. Also

limit of bolts or fittings

tions not tight

refer to paragraph 5-3a( I )(,g)

Current in excess of breaker rating

Check breaker applications or

Requires system study and possible

Short-circuit current level above

modify circuit by decreasing load

replacement with breaker having

interrupting rating of breaker

adequate interrupting capacity

Correct bus or cable arrangement

Inductive heating

FAILURE TO TRIP

5-4. Medium voltage elements.

Travel of tripping device does not Adjust or replace tripping device

provide positive release of tripping

a. Circuit breakers. Medium voltage switchgear

latch

uses oil, air-blast, or vacuum circuit breakers. Usu-

Worn or damaged trip unit parts

Replace trip unit

ally the circuit breakers have draw-out construction

to permit removal of an individual breaker from the

Correct binding condition or re-

Mechanical binding in overcurrent

place overcurrent trip device

trip device

enclosure for inspection or maintenance without de-

energizing the main bus. All of these circuit break-

Tighten, connect, or replace electri-

Electrical connectors for power

ers can quickly interrupt and extinguish the electric

cal connectors

sensor loose or open

arc that occurs between breaker contacts when the

Loose or broken power sensor con- Tighten or re-connect tap coil tap

contacts are separated.

connections

nections

5-9

|

|

|

|

||