Custom Search

|

|

|

||

MIL-HDBK-1013/12

a) Worksheets (see Appendix B):

1) Safevue Date Entry (SDE)

<1> Enter Critical Damping Percent. If

column (l) of the Safevue Data Entry

Stop

worksheet (see Appendix B for all

worksheets) is not blank, enter the value

and press the "Enter" key. If column (l) is

blank, simply press the "Enter" key.

Proceed to <2>.

<1> Enter Critical

<2> Enter Number of Integration Time Steps.

Damping Percent

If column (m) of the Safevue Data Entry

worksheet is not blank, enter the value and

press the "Enter" key. If column (m) is

blank, simply press the "Enter" key.

<2> Enter Number

Proceed to <3>.

of Integration Time

<3> Enter Probability of Failure of Glass. If

Steps

column (n) of the Safevue Data Entry

worksheet is not blank, enter the value and

press the "Enter" key. If column (n) is

<3> Enter

blank, simply press the "Enter" key.

Probability of

Proceed to <4>.

Failure for Glass

<4> Choose Resistance Function. Use the

cursor keys to highlight Beason-Vallabhan

on the Choose Resistance Function

<4> Choose

Generator menu. Press the "Enter" key to

Resistance

select Beason-Vallabhan as the resistance

Function

function generator. Refer to the Safevue

User's Manual for descriptions of the

resistance function generators included with

Safevue. Proceed to <5>.

<5> Start

<5> Start Analysis. Safevue displays a table of

Analysis

segments from which the resistance

function is built. Refer to the Safevue

User's Manual for guidance on interpreting

the composite resistance function. Press

Stop

the `C' key to begin analysis. If this is an

analysis for a selection application, return

to Figure C-13. Otherwise, return to Figure

C-1.

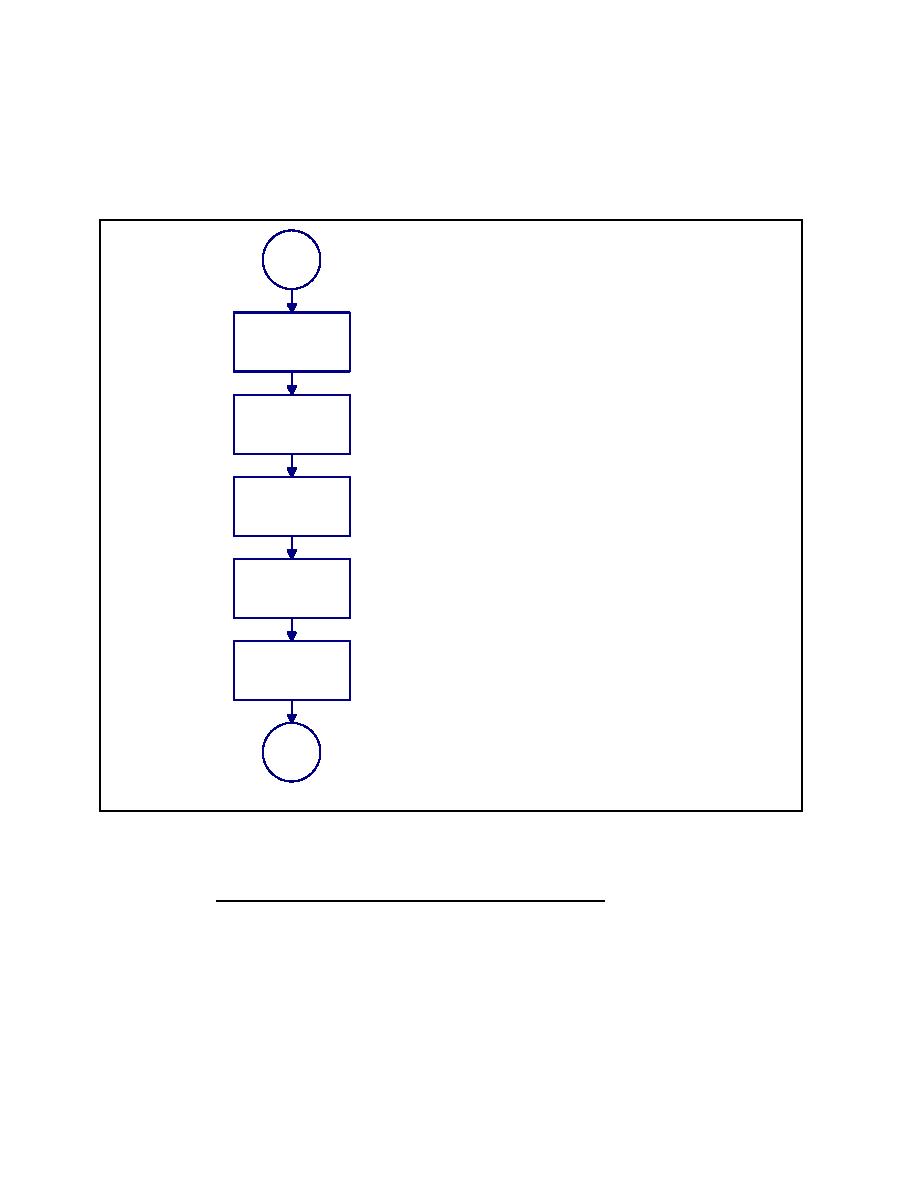

Figure C-12

Process Chart and Description: Algorithm Data Entry Procedure

C.12

Safevue Selection Analysis Procedure. This procedure

helps to select a glazing system that will withstand blast

loading. It provides a set of structures that step an analyst

through the Safevue computer program from data entry through

results analysis. A process chart and description of the

procedure are shown in Figure C-13 and Figure C-14, respectively.

131

|

|

|

|

||